Have you ever scrolled through social media, utterly captivated by those vibrant, custom-made stickers, professional-looking labels, or unique decals that seem to pop with personality? Perhaps you’ve dreamt of turning your own digital art into tangible, durable creations, or giving your small business products that polished, branded edge. If so, you’re not alone. The world of custom vinyl printing is a vibrant, ever-expanding universe, and the printable vinyl printer is your indispensable spaceship to navigate it.

Trust me, I know the feeling. I remember vividly my own early days, staring at an array of intimidating tech specs and confusing vinyl types, feeling a mix of excitement and utter bewilderment. I once spent an entire weekend trying to figure out why my prints were smudging, only to discover I was using the wrong ink type for my vinyl. It was a face-palm moment, but a crucial learning experience! That struggle, that initial hurdle, is precisely why I’m here. This isn't just an article; it's a deep dive, a heartfelt conversation, and a comprehensive roadmap designed to demystify the printable vinyl printer and empower you, whether you’re a complete novice or a seasoned crafter looking to level up. We’re going to explore everything from the fundamental differences between printer types to advanced techniques that will make your creations truly shine. Get ready to transform your ideas from pixels to perfectly printed vinyl!

---

Table of Contents

- [The Heart of the Operation: Inkjet vs. Laser Printable Vinyl Printers](#the-heart-of-the-operation-inkjet-vs-laser-printable-vinyl-printers)

- [Unleashing Your Creativity: Top Printable Vinyl Printers for Hobbyists & Crafters](#unleashing-your-creativity-top-printable-vinyl-printers-for-hobbyists--crafters)

- [Powering Your Passion: Best Printable Vinyl Printers for Small Businesses & Professionals](#powering-your-passion-best-printable-vinyl-printers-for-small-businesses--professionals)

- [Beyond the Printer: Understanding Printable Vinyl Materials](#beyond-the-printer-understanding-printable-vinyl-materials)

- [The Digital Canvas: Software, Design, and Calibration for Perfect Prints](#the-digital-canvas-software-design-and-calibration-for-perfect-prints)

- [Troubleshooting Tales: Conquering Common Printable Vinyl Printer Headaches](#troubleshooting-tales-conquering-common-printable-vinyl-printer-headaches)

- [Mastering the Art: Advanced Techniques for Durable & Stunning Vinyl Creations](#mastering-the-art-advanced-techniques-for-durable--stunning-vinyl-creations)

- [Budget-Friendly Brilliance: Getting Started with Printable Vinyl Printing on a Shoestring](#budget-friendly-brilliance-getting-started-with-printable-vinyl-printing-on-a-shoestring)

- [The Future is Here: Innovations & Emerging Trends in Printable Vinyl Printing](#the-future-is-here-innovations--emerging-trends-in-printable-vinyl-printing)

- [How to Choose the Best Printable Vinyl Printer for Your Needs](#how-to-choose-the-best-printable-vinyl-printer-for-your-needs)

- [Common Pitfalls to Avoid](#common-pitfalls-to-avoid)

- [Advanced Tips for Experts](#advanced-tips-for-experts)

- [Conclusion](#conclusion)

---

The Heart of the Operation: Inkjet vs. Laser Printable Vinyl Printers

When you first dive into the world of printable vinyl printers, the very first fork in the road you'll encounter is the fundamental choice between inkjet and laser technology. This isn't just a technical detail; it's a decision that will profoundly impact your projects, your budget, and your overall printing experience. Let's break down these two titans of the printing world with an empathetic eye, understanding that for many, this is where the real learning begins.

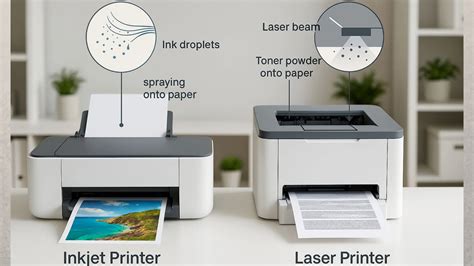

1. Inkjet Printers: The Versatile Artist's Choice

- How They Work: Inkjet printers spray microscopic droplets of liquid ink onto the vinyl surface. This allows for incredible color blending and photo-realistic quality.

- Pros:

- Vibrant Colors & Gradients: If your designs feature intricate details, smooth color transitions, and a broad spectrum of hues, an inkjet is usually your go-to. They excel at producing photo-quality images.

- Cost-Effective Entry: Generally, the initial purchase price of an inkjet printable vinyl printer is lower than a laser equivalent, making them a popular choice for hobbyists and beginners.

- Wider Vinyl Compatibility: Inkjets tend to be more forgiving with various types of printable vinyl, especially those designed with special coatings to absorb the liquid ink effectively.

- Personal Scenario: "I remember setting up my first inkjet for a friend's wedding invitations that required delicate watercolor designs. The way it rendered those soft gradients on the printable vinyl was simply breathtaking. It truly captured the essence of her vision."

- Cons:

- Slower Print Speeds: Inkjets typically print slower than laser printers, which can be a consideration if you're producing large batches.

- Water Sensitivity: Traditional inkjet inks are water-soluble. This means you absolutely *must* use waterproof printable vinyl or laminate your prints to prevent smudging or running when exposed to moisture.

- Ink Costs: While the printer itself might be cheaper, ink cartridges can add up, especially if you print frequently. This is where understanding yield and replacement costs becomes crucial.

- Clogging Potential: If not used regularly, inkjet print heads can clog, leading to streaky prints and frustrating maintenance. This is a common pain point for casual users.

2. Laser Printers: The Durable Workhorse

- How They Work: Laser printers use a laser beam to project an image onto a photosensitive drum. Toner (a dry, powdered pigment) adheres to the charged areas, is transferred to the vinyl, and then fused onto the surface with heat and pressure.

- Pros:

- Exceptional Durability: Because toner is fused onto the vinyl, laser prints are inherently more durable, water-resistant, and often UV-resistant right out of the printer. No extra lamination needed for basic protection!

- Faster Print Speeds: For bulk printing, laser printers are significantly faster, making them ideal for small businesses or those with high-volume needs.

- Lower Cost Per Print (Long-Term): While toner cartridges are more expensive upfront, they yield far more prints than inkjet cartridges, often resulting in a lower cost per page over time.

- Sharp, Crisp Text & Lines: Laser printers excel at producing incredibly sharp text and fine lines, which is fantastic for labels, barcodes, or designs requiring precision.

- Personal Scenario: "When I started my small business selling custom product labels, the switch to a laser printable vinyl printer was a game-changer. The sheer speed and the inherent durability of the prints meant I could fulfill orders faster and with greater confidence in their longevity."

- Cons:

- Higher Upfront Cost: Laser printers, especially color models suitable for vinyl, typically have a higher initial purchase price.

- Limited Color Fidelity: While modern color laser printers are good, they generally can't match the photographic quality and subtle color blending of a good inkjet. Gradients can sometimes appear banded.

- Heat Sensitivity of Vinyl: The heat generated during the fusing process can warp or damage certain types of printable vinyl not specifically designed for laser printers. You *must* use laser-compatible vinyl.

- Thicker Media Challenges: Some laser printers struggle with thicker media, which can include certain types of printable vinyl. Always check the printer's specifications for media thickness limits.

3. Hybrid Solutions & Considerations

- Some advanced users might even consider having both: an inkjet for high-quality, vibrant graphics and a laser for durable text-heavy labels or bulk runs.

- My Subjective Tip: For most hobbyists starting out, I genuinely believe an inkjet printable vinyl printer offers the best balance of initial cost, versatility, and color vibrancy, *provided* you commit to using waterproof vinyl or laminating. It allows for more creative freedom with less upfront investment.

Choosing between inkjet and laser isn't about one being inherently "better"; it's about aligning the technology with your specific needs, project types, and budget. Take the time to consider what you'll be printing most often, and you'll make the right choice.

Unleashing Your Creativity: Top Printable Vinyl Printers for Hobbyists & Crafters

For the creative soul, the DIY enthusiast, and the budding crafter, a printable vinyl printer is more than just a piece of equipment; it's a gateway to endless possibilities. These printers are often characterized by their user-friendliness, reasonable price points, and excellent color reproduction, allowing you to bring your artistic visions to life on stickers, decals, and custom embellishments. Here are some of the top contenders and considerations for hobbyists.

1. Epson EcoTank Series (e.g., ET-2800, ET-2850):

- Why it's great: These are cartridge-free printers with refillable ink tanks. This drastically reduces the cost of ink over time, a huge win for hobbyists who print frequently. They produce vibrant, high-quality prints and are often highly compatible with various printable vinyl types.

- Personal Scenario: "My sister, who makes personalized party favors, swears by her EcoTank. She used to dread buying ink, but now she prints hundreds of custom labels and stickers for her events without breaking the bank. It really took the stress out of her creative process."

2. Canon PIXMA Series (e.g., TS6420a, G3270 MegaTank):

- Why it's great: Canon PIXMA printers are renowned for their photo-quality output, making them excellent for designs that require rich colors and fine details. Many models are very user-friendly with intuitive interfaces. The MegaTank series offers similar cost savings to Epson's EcoTanks.

- Feature Highlight: Often come with robust wireless connectivity, making it easy to print from your phone or tablet.

3. HP Envy Series (e.g., Envy 6055e, Envy Photo 7855):

- Why it's great: HP Envy printers are popular for their affordability and decent print quality. They are often a good entry-level option for those just dipping their toes into printable vinyl. Look for models with Instant Ink subscriptions to save on ink costs.

- Consideration: Ensure you check the maximum media thickness if you plan on using thicker vinyl.

4. Brother Inkjet Printers (e.g., MFC-J4335DW):

- Why it's great: Brother offers reliable inkjet printers that often have good paper handling and relatively affordable ink. They are solid all-around performers for general home use, including printable vinyl projects.

- Unique Point: Some Brother models are known for their robust build quality, standing up to consistent use.

5. Small Format Photo Printers (e.g., Canon SELPHY CP1500 - with caveats):

- Why it's great: While not strictly "printable vinyl printers" in the traditional sense, some advanced crafters use these for small, specific vinyl projects if they can find compatible vinyl sheets or adapt materials. They are compact and produce excellent photo quality.

- Important Caveat: Compatibility with standard printable vinyl is very limited, and specific media might be hard to source. This is for experimental crafters only!

6. Understanding DPI (Dots Per Inch):

- For crafters, a higher DPI (e.g., 4800 x 1200 dpi or higher) generally means sharper images and smoother gradients, which is essential for detailed stickers and art prints.

7. Connectivity Options:

- Look for Wi-Fi, USB, and potentially Bluetooth connectivity for maximum flexibility in your crafting space.

8. Automatic Document Feeder (ADF):

- While not strictly necessary for vinyl, an ADF can be handy if you also use your printer for other crafting needs or general home printing.

9. Print and Cut Compatibility:

- Many crafters pair their printable vinyl printer with a cutting machine like a Cricut or Silhouette. Ensure your printer has reliable print quality for registration marks. "This pairing truly revolutionized my sticker-making process. I print, then the Cricut perfectly cuts them out – pure magic!"

10. Quiet Mode:

- If you're crafting in a shared space or late at night, a printer with a "quiet mode" can be a blessing.

11. Refillable Ink Tanks vs. Cartridges:

- For hobbyists, I highly recommend considering printers with refillable ink tanks (like Epson EcoTank or Canon MegaTank). The long-term savings on ink are significant and allow for more creative experimentation without worrying about cost.

12. Ease of Maintenance:

- Look for printers with relatively easy-to-clean print heads or readily available cleaning cycles to keep your prints crisp and clear.

Choosing a printable vinyl printer for crafting is an exciting journey. Prioritize color quality, ease of use, and long-term ink costs, and you’ll find a reliable partner for all your creative endeavors.

Powering Your Passion: Best Printable Vinyl Printers for Small Businesses & Professionals

When your passion turns into profit, your printable vinyl printer needs to step up its game. For small businesses, Etsy sellers, sign makers, or those providing custom decal services, reliability, speed, durability, and cost-efficiency become paramount. These printers are built to handle higher volumes, offer professional-grade output, and often come with features designed for a more demanding workflow.

1. Wide Format Inkjet Printers (e.g., Epson SureColor Series, Canon imagePROGRAF Series):

- Why they're great: These are serious machines, designed for large-format printing, often up to 24 inches or even wider. They offer incredible print quality, color accuracy, and often use pigment-based inks which are inherently more durable and water-resistant than dye inks.

- Ideal For: Large decals, wall graphics, custom signage, vehicle wraps (when paired with appropriate vinyl and lamination).

- Personal Scenario: "When my custom sticker business started booming, I invested in an Epson SureColor. The ability to print larger sheets meant I could produce more stickers per run, and the pigment inks gave my products the professional, durable finish my customers expected. It was a big investment, but it paid for itself quickly."

2. Color Laser Printers (e.g., HP Color LaserJet Pro series, Brother MFC-L8900CDW):

- Why they're great: As discussed, laser printers excel in speed and durability. For businesses that need high-volume labels, product packaging, or durable indoor signage, a color laser printable vinyl printer is an excellent choice. Toner is inherently waterproof and UV-resistant to a degree.

- Feature Highlight: Many business-grade laser printers offer duplex printing and robust network connectivity, essential for busy offices.

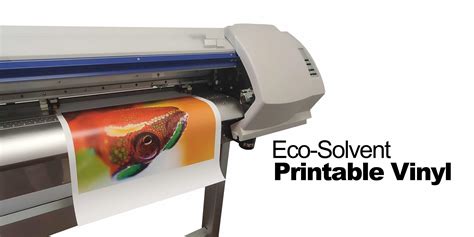

3. Eco-Solvent Printers (Specialized, beyond standard home/office):

- Why they're great: While a step up in investment, eco-solvent printers are the gold standard for truly professional, outdoor-durable vinyl prints. They use inks that are highly resistant to water, UV, and abrasion, without needing lamination for basic protection.

- Consideration: These are large, specialized machines requiring ventilation and a significant budget, usually for dedicated sign shops or print houses.

4. Roll-to-Roll Capabilities:

- For high-volume production, look for printable vinyl printers that can handle rolls of vinyl rather than just sheets. This allows for continuous printing and integrates seamlessly with roll-fed cutting machines.

5. Advanced Color Management:

- Professionals need precise color accuracy. Look for printers with good ICC profile support and calibration options to ensure your prints match your screen and client expectations.

- Expert Tip: Investing in a colorimeter for display calibration is crucial for professional color matching.

6. Print Speeds (PPM - Pages Per Minute):

- Time is money. A faster printer means more output and quicker fulfillment of orders. Prioritize models with high PPM, especially for color prints.

7. Connectivity & Networking:

- Seamless integration into your office network, Wi-Fi Direct, and mobile printing capabilities are essential for a busy professional environment.

8. Media Handling:

- Ensure the printer can handle a variety of vinyl thicknesses and finishes. Look for straight-through paper paths if you anticipate using very thick or rigid vinyl.

9. Maintenance & Support:

- For business-critical equipment, reliable customer support, warranty options, and readily available spare parts are paramount. Downtime can cost you money.

10. Cost Per Print Analysis:

- Beyond the initial purchase, meticulously calculate the cost per print for ink/toner and media. This is a critical factor for profitability in a business setting.

11. Security Features:

- For professional environments, printers with advanced security features (e.g., secure print release, user authentication) can be important.

12. Integration with Design Software:

- Ensure robust drivers and compatibility with professional design software like Adobe Illustrator, Photoshop, CorelDRAW, and CAD programs.

Investing in a professional-grade printable vinyl printer is a strategic business decision. Focus on machines that offer a blend of high-quality output, durability, speed, and long-term cost-effectiveness to support your growth.

Beyond the Printer: Understanding Printable Vinyl Materials

Your printable vinyl printer is only half the equation; the other crucial component is the printable vinyl itself. This isn't a one-size-fits-all product; the vast array of vinyl types, finishes, and adhesive properties can be overwhelming. Understanding these nuances is key to achieving the perfect result for your specific project.

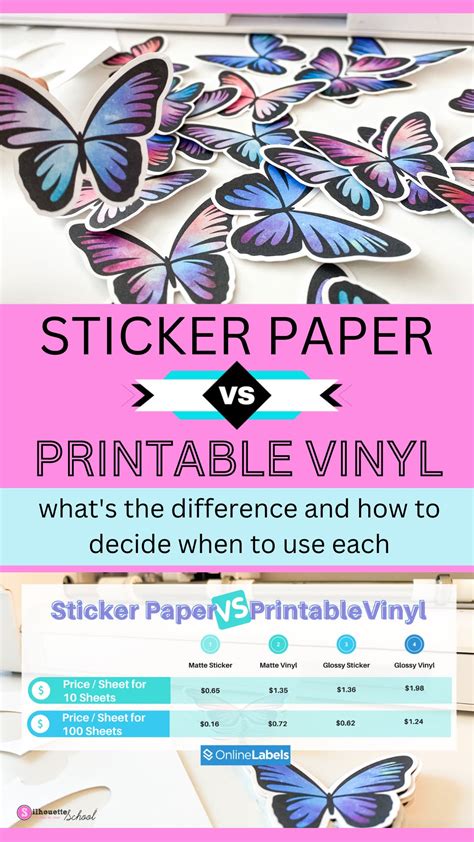

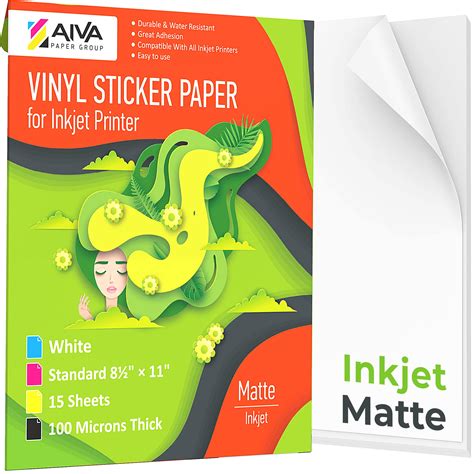

1. Inkjet Printable Vinyl vs. Laser Printable Vinyl:

- Crucial Distinction: This is the most important factor. Inkjet vinyl has a special absorbent coating to hold liquid inks. Laser vinyl is designed to withstand heat and accept toner without melting or smudging. Using the wrong type can ruin your print, damage your printer, or both!

- Personal Anecdote: "I once tried to use a generic 'printable vinyl' with my laser printer, assuming it was universal. The sheet melted and jammed inside, requiring a costly repair. Learn from my mistake – always check compatibility!"

2. Finishes: Matte, Glossy, and Clear:

- Matte: Non-reflective, offers a sophisticated, subtle look. Great for designs where you want to minimize glare and have a more artistic, muted feel.

- Glossy: Highly reflective, vibrant colors, often used for stickers, labels, and decals that need to pop. Think of classic bumper stickers.

- Clear/Transparent: Allows the background to show through, perfect for window decals, product labels where you want a "no-label" look, or layering effects.

3. Adhesive Types: Permanent vs. Removable:

- Permanent Adhesive: Strong, long-lasting bond. Ideal for car decals, outdoor signs, product labels, or anything you want to stay put. Removing it often leaves residue or damages the surface.

- Removable Adhesive: Designed for temporary applications, easy to peel off without residue. Great for wall decals, temporary signage, or repositionable labels.

4. Waterproof/Water-Resistant Vinyl:

- Many inkjet printable vinyls are advertised as "waterproof." This usually means they have a top coating that prevents ink from running immediately. For true outdoor durability and longevity, lamination is almost always recommended, even with "waterproof" vinyl.

- My Subjective Opinion: If you're printing anything that will be handled frequently or exposed to moisture, always opt for waterproof printable vinyl and seriously consider lamination. It's a game-changer for durability.

5. Specialty Vinyls:

- Holographic/Glitter: Adds a unique, eye-catching shimmer to your designs. Popular for decorative stickers and crafts.

- Metallic (Gold, Silver): Provides a luxurious, reflective metallic effect. Great for premium product labels or special occasion decals.

- Vinyl for Heat Transfer (HTV): While some HTV is printable, it's a different category often requiring a specific type of printer (sublimation or specialized pigment inkjet) and a heat press, rather than a standard printable vinyl printer.

- Glow-in-the-Dark: Fun for novelty stickers and safety applications.

- UV Resistant: Some vinyls come with inherent UV resistance, but lamination is still the best defense against fading from sunlight.

6. Thickness (Mil or Microns):

- Vinyl thickness impacts how easy it is to feed through your printer and how durable the final product feels. Thicker vinyls (higher mil count) are generally more robust. Always check your printer's media thickness specifications.

7. Choosing the Right Brand:

- Popular brands like OnlineLabels, Silhouette, Cricut, Avery, and Neato offer various printable vinyls. Experiment with a few to find what works best with your printer and your specific projects.

8. Storage of Vinyl:

- Store unused printable vinyl flat in its original packaging or a sealed bag to prevent curling, dust accumulation, and moisture absorption, which can affect print quality.

9. Laminating Film:

- Often, after printing on inkjet vinyl, you'll apply a clear laminating film over the top. This adds a protective layer against scratches, water, and UV fading, significantly extending the life of your vinyl prints.

10. Test Prints:

- Before committing to a large batch, always do a small test print on a scrap piece of your chosen printable vinyl. This helps you check color accuracy, ink drying time, and overall compatibility.

11. Surface Prep for Application:

- Regardless of the vinyl type, the surface you apply it to should always be clean, dry, and smooth for optimal adhesion.

12. Environmental Considerations:

- Some vinyls are more environmentally friendly than others, with options like PVC-free or biodegradable materials becoming available. If sustainability is a concern, research these options.

Understanding the characteristics of printable vinyl is as crucial as choosing the right printable vinyl printer. By pairing the right printer with the right material, you'll unlock a world of possibilities and ensure your creations stand the test of time.

The Digital Canvas: Software, Design, and Calibration for Perfect Prints

Once you have your printable vinyl printer and your chosen vinyl, the magic truly begins on your screen. The journey from a digital idea to a vibrant, physical print requires careful attention to design software, image quality, and printer calibration. This is where your expertise grows, and your prints go from good to glorious.

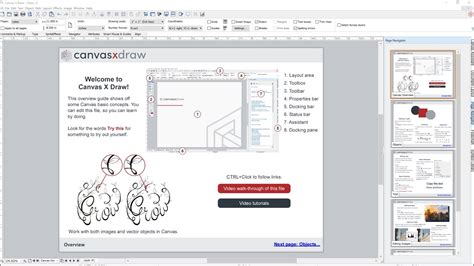

1. Choosing Your Design Software:

- Adobe Illustrator/Photoshop: Industry standards for professional graphic design. Illustrator is vector-based (scalable without pixelation), ideal for logos, text, and sharp graphics. Photoshop is raster-based (pixel-based), best for photos and intricate artwork.

- Affinity Designer/Photo: Excellent, one-time purchase alternatives to Adobe, offering similar powerful features for both vector and raster design.

- Canva/PicMonkey: User-friendly, web-based tools for beginners. Great for simple designs, templates, and quick edits. May have limitations for very high-resolution or complex vinyl projects.

- Cricut Design Space/Silhouette Studio: Free software that comes with popular cutting machines. While primarily for cutting, they have basic design and "print then cut" features, perfect for sticker making.

- My Subjective Opinion: For serious crafters and small businesses, learning a vector-based program like Illustrator or Affinity Designer is a game-changer. It gives you unparalleled control and ensures your designs look crisp at any size.

2. Image Resolution and Quality (DPI/PPI):

- For high-quality vinyl prints, aim for at least 300 DPI (dots per inch) or PPI (pixels per inch) at your final print size. Lower resolutions will result in pixelated or blurry prints.

- Rule of Thumb: Design at the largest size you anticipate printing, and then scale down if needed. Scaling up always degrades quality.

3. Color Modes: RGB vs. CMYK:

- RGB (Red, Green, Blue): Used for digital screens (monitors, phones). Has a wider color gamut.

- CMYK (Cyan, Magenta, Yellow, Black): Used for print. Has a more limited color gamut.

- Crucial Tip: Design in CMYK mode if possible, especially for professional projects. What looks vibrant in RGB on screen might appear duller when printed in CMYK. If you design in RGB, be prepared for potential color shifts.

- Personal Scenario: "I once designed a stunning logo in RGB, and when I printed it on my printable vinyl printer, the bright blue turned into a muted teal. It was a harsh lesson in understanding color modes, and now I always start in CMYK for print projects."

4. Printer Calibration and ICC Profiles:

- Monitor Calibration: Use a colorimeter to calibrate your monitor regularly. This ensures that the colors you see on screen are as accurate as possible.

- Printer Profiles (ICC Profiles): These files tell your printer how to accurately reproduce colors on specific paper/vinyl types. Many printer manufacturers provide profiles, and some premium vinyl brands offer custom profiles for their products.

- Benefit: Proper calibration minimizes color discrepancies between your screen and your printed vinyl, saving you ink and frustration.

5. Test Prints and Proofing:

- Always, always, *always* do a small test print on your actual printable vinyl before a large batch. This allows you to check colors, resolution, and overall appearance.

- Soft Proofing: In professional design software, you can "soft proof" your design, which simulates how it will look when printed using a specific ICC profile.

6. Bleed and Margins:

- Bleed: Extend your background colors or images slightly beyond the cut line. This ensures that if there's any slight misalignment during cutting, you don't end up with an unsightly white edge.

- Margins: Keep important text and design elements safely within the cut line to prevent them from being accidentally trimmed.

7. Vector vs. Raster Graphics:

- Vector (e.g., SVG, AI, EPS): Ideal for logos, text, and illustrations. Can be scaled infinitely without losing quality.

- Raster (e.g., JPG, PNG, TIFF): Best for photos and complex images. Quality depends on resolution.

- Recommendation: Use vector graphics for anything that needs crisp lines or might be resized.

8. Working with Cutting Machine Software:

- If you're doing "print then cut" with a Cricut or Silhouette, you'll need to understand how to add registration marks, resize images, and ensure your design fits within the printable area of your cutting mat.

9. Font Management:

- Ensure all fonts used in your design are either embedded in the file or converted to outlines/paths to prevent font substitution issues when printing or sharing files.

10. File Formats for Printing:

- PDF: Excellent for print-ready files, preserves fonts and layouts.

- TIFF/PNG: Good for high-quality raster images, especially PNG for transparent backgrounds.

- JPG: Suitable for photos, but can suffer from compression artifacts.

- AI/EPS: Native vector formats, ideal for professional print shops.

11. Print Settings in Your Printer Driver:

- Always select the correct media type (e.g., "Glossy Photo Paper," "Matte Photo Paper," or a custom setting if available) that closely matches your printable vinyl. Choose the highest print quality setting for best results.

12. Environmental Factors:

- Humidity and temperature can slightly affect how ink dries and how vinyl behaves. Keep your workspace consistent.

Mastering the digital canvas is an ongoing process of learning and refinement. By paying attention to resolution, color modes, and calibration, you'll ensure your printable vinyl printer consistently produces prints that perfectly match your creative vision.

Troubleshooting Tales: Conquering Common Printable Vinyl Printer Headaches

Even the most seasoned vinyl printer enthusiast runs into snags. It's part of the creative process! Rather than letting frustration win, let's arm ourselves with knowledge to tackle the most common issues you might face with your printable vinyl printer. Remember, every problem solved is a step closer to expertise.

1. Ink Smudging/Running:

- Cause: Most often, you're using standard inkjet ink on non-waterproof printable vinyl, or the vinyl isn't specifically designed for inkjet use. Insufficient drying time is another culprit.

- Solution:

- Use Waterproof Vinyl: Switch to printable vinyl explicitly labeled "waterproof" for inkjet printers.

- Allow Drying Time: Give prints ample time to dry (often 10-30 minutes, sometimes longer) before handling or laminating.

- Laminate: For ultimate durability and water resistance, always laminate inkjet prints.

- Check Printer Settings: Ensure you've selected the correct media type (e.g., "Glossy Photo Paper" instead of plain paper) as this affects ink saturation.

2. Fading Colors / Poor Vibrancy:

- Cause: Incorrect color profile, low-quality ink, old ink, designing in RGB for CMYK printing, or prolonged UV exposure.

- Solution:

- Design in CMYK: As discussed, design your files in CMYK.

- Calibrate Monitor/Printer: Use ICC profiles and calibrate your monitor.

- Quality Ink/Toner: Use genuine or high-quality compatible inks/toners.