Let's be honest, in the grand scheme of running a business or even just organizing your life, labels often feel like an afterthought. A necessary evil, perhaps. But trust me, as someone who once had a crucial batch of product labels melt off in a humid warehouse, leaving me with a logistical nightmare, I can tell you that thermal transfer printable labels are anything but an afterthought. They are the unsung heroes of durability, clarity, and genuine peace of mind.

I once started a small e-commerce business, brimming with optimism. I thought all labels were created equal. Boy, was I wrong! My first batch of "standard" shipping labels smudged, faded, and peeled off mid-transit, leading to some frantic phone calls from confused customers and more than a few returns. That’s when I truly discovered the magic of thermal transfer technology. It was a hard lesson, but it showed me the critical difference that the right labeling solution can make for everything from inventory to branding. If you’re looking for labels that stand the test of time, environment, and handling, you're in the right place.

Why Thermal Transfer Labels Are Your Unsung Heroes

So, what makes thermal transfer printable labels so special, and why should you care? It boils down to their unparalleled durability and print quality. Unlike direct thermal labels that react to heat directly and fade over time, thermal transfer labels use a ribbon that melts onto the label material, creating a permanent bond. This isn't just a technical detail; it's a game-changer for longevity and readability.

- Unrivaled Durability: These labels resist scratches, smudges, chemicals, extreme temperatures, and UV exposure. Perfect for products with long shelf lives or items exposed to harsh environments.

- Superior Print Quality: Expect crisp, clear, high-resolution text, graphics, and barcodes that remain legible for years. Essential for scannable inventory and professional branding.

- Versatility in Materials: From paper to synthetics (polyester, polypropylene, vinyl), you can find a thermal transfer label for almost any surface or condition.

- Cost-Effectiveness in the Long Run: While the initial setup might seem a tad more involved, the lack of reprinting due to fading or damage saves significant time and money over time.

- Wide Application Range: From asset tracking and inventory management to product identification, circuit board labeling, and even outdoor signage, their uses are incredibly diverse. I remember one tricky project where generic labels just wouldn't cut it for outdoor equipment – a specific thermal transfer setup saved the day!

- Compliance & Trust: For industries requiring strict compliance (e.g., pharmaceuticals, automotive), the permanence and reliability of thermal transfer labels are often a non-negotiable requirement.

- Sharp Barcode Readability: For logistics and inventory, clear, permanent barcodes are paramount. Thermal transfer excels here, minimizing scanning errors and speeding up operations.

Decoding the Duo: Labels & Ribbons – A Match Made in Printing Heaven

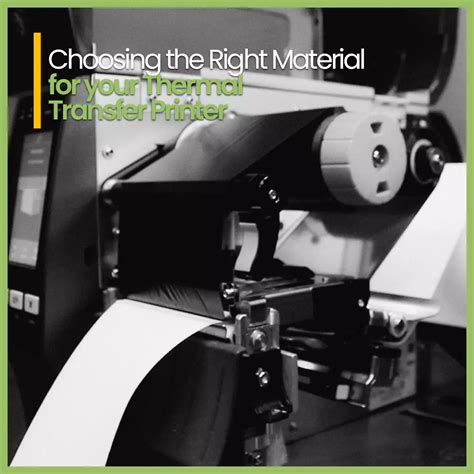

The secret sauce of thermal transfer printable labels lies in the perfect pairing of the label material with the correct thermal transfer ribbon. It’s like a finely tuned engine – the right parts working together make all the difference. Understanding this synergy is key to unlocking the full potential of your labeling.

- Wax Ribbons: The most economical option, ideal for paper labels in general-purpose applications like shipping or retail tags. They offer good durability against smudges but are sensitive to chemicals and moisture.

- Wax-Resin Ribbons: A fantastic all-rounder. Combining wax and resin, they offer better scratch, smudge, and chemical resistance than pure wax, making them suitable for coated paper and some synthetic labels (e.g., polypropylene).

- Resin Ribbons: The heavyweights of durability. Made mostly of resin, these are designed for synthetic labels (polyester, vinyl) and provide extreme resistance to chemicals, abrasions, and high temperatures. If your label needs to survive a nuclear winter, this is your go-to.

- Matching is Mandatory: Always match your ribbon type to your label material. A resin ribbon on a plain paper label is overkill and won't stick properly, while a wax ribbon on a synthetic label will just flake off. It’s a common mistake I’ve seen many beginners make!

- Understanding Print Head Protection: The ribbon also protects your printer's print head from direct contact with the label, extending the life of this critical (and expensive) component.

- Outside Wound vs. Inside Wound: Ribbons come wound differently. Ensure your ribbon matches your printer's requirements – checking your printer manual is always the first step.

- Ribbon Core Size: These vary. Make sure the core fits your printer's spindle. Seems basic, but it's a frequent hiccup!

- Color Options: While black is standard, thermal transfer ribbons come in a variety of colors, allowing for color-coding or branding elements.

- Environmental Considerations: Some ribbons are specifically designed for specific environmental challenges, like extreme cold storage or outdoor exposure.

Beyond Barcodes: Diverse Applications for Thermal Transfer Labels

While barcodes are a major application, the versatility of thermal transfer printable labels goes far beyond simple scanning. Their ability to handle diverse conditions makes them indispensable across a multitude of industries and use cases.

- Asset Tracking: Labeling valuable equipment, tools, and IT assets with durable barcodes and serial numbers ensures accurate inventory and accountability.

- Product Identification: From food packaging (think freezer labels!) to electronics, these labels provide clear, long-lasting product info, ingredients, or specifications.

- Warehouse & Logistics: Ideal for shelving, bins, pallets, and shipping labels, ensuring seamless operations in demanding environments.

- Healthcare: Used for specimen tracking, patient wristbands, pharmaceutical labeling, and laboratory samples where clarity and resistance to chemicals are paramount.

- Automotive: For parts identification, VIN labels, and under-the-hood applications where labels face heat, oil, and vibrations.

- Outdoor & Garden: Labeling plants, equipment, or signage that will be exposed to sun, rain, and temperature fluctuations.

- Retail & Apparel: High-quality swing tags, price tags, and care labels that need to withstand handling and not fade.

- Circuit Board & Electronics Labeling: Tiny, heat-resistant labels for internal components or serial numbers on delicate electronics.

- Compliance Labeling: Meeting regulatory requirements for safety, warnings, or hazardous materials with durable, clear labels.

Common Pitfalls & Pro Tips: Mastering Your Thermal Transfer Workflow

Even with the best thermal transfer printable labels, there are nuances that can trip you up. Learning from others' mistakes (and my own!) can save you a lot of headache, wasted labels, and frustration. Trust me, you don’t want your critical "DO NOT FREEZE" label dissolving in the rain.

- The Ribbon-Label Mismatch: This is the #1 culprit for poor print quality or failed labels. Always double-check your ribbon and label material compatibility. If your print is smudgy or flakes off easily, this is likely the issue.

- Incorrect Heat/Speed Settings: Your thermal transfer printer has settings for heat (darkness) and print speed. Too hot can burn through the ribbon or label; too cold leads to faint prints. Too fast can reduce quality. Experiment with your printer's manual recommendations.

- Dirty Print Head: Dust, adhesive residue, or even just general grime can accumulate on your print head, leading to white lines or gaps in your print. Clean it regularly with an approved cleaner.

- Improper Label Loading: Labels must be loaded correctly, aligned with the sensors, and feeding smoothly. Wrinkles or jams are often due to poor loading.

- Ignoring Environmental Factors: While durable, no label is invincible. Ensure the label's material and ribbon are rated for the *actual* conditions it will face (e.g., constant UV exposure, specific chemical splashes).

- Storing Ribbons & Labels Incorrectly: Store them in a cool, dry place, away from direct sunlight. High humidity or extreme temperatures can degrade both.

- Don't Overlook Adhesives: The label material is one thing, but the adhesive is another. Permanent, removable, aggressive, all-temp – pick the right one for your surface and application. I personally find a high-tack permanent adhesive works best for most industrial applications; it's saved me countless re-labeling tasks.

- Test, Test, Test: Especially for new applications or materials, always run small test batches. Put them through the paces they’ll encounter in real life.

- Printer Maintenance is Key: Beyond the print head, regularly clean rollers and ensure firmware is updated. A well-maintained printer lasts longer and performs better.

Investing Wisely: Choosing the Right Thermal Transfer Printer & Software

Your thermal transfer printable labels are only as good as the printer putting ink on them and the software telling it what to do. Making the right investment here ensures efficiency, quality, and scalability for your labeling needs.

- Desktop Printers: Ideal for smaller volumes (a few hundred to a couple thousand labels per day). Compact, affordable, and great for office or retail environments.

- Industrial Printers: Designed for high-volume, continuous printing (thousands of labels per day). More robust, faster, and often come with advanced features like internal rewinders or cutters.

- Mobile Printers: For on-the-go labeling in warehouses or field service. Great for situations where you need to print labels exactly where they're needed.

- Print Resolution (DPI): Common resolutions are 203 dpi, 300 dpi, and 600 dpi. Higher DPI means sharper print, especially for small text, intricate graphics, or very dense barcodes. For most general uses, 203-300 dpi is fine, but for detailed electronics labels, 600 dpi might be necessary.

- Connectivity Options: USB, Ethernet (for network printing), Wi-Fi, and Bluetooth are common. Choose what integrates best with your existing infrastructure.

- Label Design Software: Many printers come with basic software, but investing in a robust label design application (like BarTender or NiceLabel) offers more control, database connectivity, and automation features.

- Driver Compatibility: Ensure the printer drivers are compatible with your operating system and any existing enterprise resource planning (ERP) or warehouse management systems (WMS).

- Scalability: Consider your future needs. Will your labeling volume increase significantly? Choose a printer that can grow with you.

- Service & Support: Look for brands with good customer service and readily available parts. When a critical label printer goes down, you want quick support.

Final Thoughts on Your Labeling Journey

Navigating the world of thermal transfer printable labels might seem daunting at first, but with a little understanding and the right approach, you'll soon be printing labels that truly work for you, not against you. Remember, a label isn't just a sticker; it's a critical piece of information, a brand ambassador, and often, a silent guardian of your inventory.

By choosing the right combination of label material, ribbon, and understanding the simple best practices, you're investing in reliability, clarity, and most importantly, saving yourself from those frantic moments I experienced with my smudged, peeling labels. So go forth, equip yourself with knowledge, and ensure your labels are always clear, crisp, and exactly where they need to be!