Have you ever looked at a lithium battery – whether it’s powering your drone, your electric bike, or the latest power tool – and wondered about the complex world behind its seemingly simple exterior? Specifically, about the labels? Trust me, you’re not alone. The journey of a lithium battery from manufacturer to end-user, or even just from your workbench to a storage shelf, is a meticulously regulated one, primarily due to its inherent power and potential risks if mishandled. And at the heart of this regulation? The labels.

For years, I was that person who just slapped on a generic warning sticker, thinking "good enough." Then came the day I had a shipment of custom battery packs held up at customs because my labels weren't compliant with the latest IATA regulations. The frustration was immense, the delays costly, and the lesson learned, invaluable. That experience hammered home the critical importance of getting lithium battery labeling right – not just for compliance, but for safety, efficiency, and ultimately, peace of mind.

This isn't just about sticking a piece of paper on a box; it's about communicating vital safety information, adhering to global regulations, and protecting everyone in the supply chain. If you’re a hobbyist, a small business owner, a logistics professional, or simply someone who wants to understand why those seemingly complex symbols exist, you’ve landed in the right place. This comprehensive guide will take you through everything you need to know about "lithium battery label printable" solutions. We'll demystify the regulations, explore your printing options, and equip you with the knowledge to label your batteries safely, effectively, and compliantly, every single time. Here’s what I learned after hours of research, countless calls to regulatory bodies, and a few close calls with my own shipments.

---

Table of Contents

- [Understanding the "Why": The Critical Importance of Lithium Battery Labels](#understanding-the-why-the-critical-importance-of-lithium-battery-labels)

- [Decoding the Details: Essential Types of Lithium Battery Labels You Can Print](#decoding-the-details-essential-types-of-lithium-battery-labels-you-can-print)

- [DIY vs. Pro: Choosing Your Lithium Battery Label Printable Solution](#diy-vs-pro-choosing-your-lithium-battery-label-printable-solution)

- [Navigating the Maze: Compliance for Different Modes of Transport and Industries](#navigating-the-maze-compliance-for-different-modes-of-transport-and-industries)

- [Designing Your Own: Unleashing Creativity (Within Compliance) for Printable Labels](#designing-your-own-unleashing-creativity-within-compliance-for-printable-labels)

- [Tools of the Trade: Software and Equipment for Your Printable Lithium Battery Labels](#tools-of-the-trade-software-and-equipment-for-your-printable-lithium-battery-labels)

- [Beyond the Sticker: Best Practices for Safe Handling, Storage, and Disposal](#beyond-the-sticker-best-practices-for-safe-handling-storage-and-disposal)

- [Troubleshooting Common Labeling Challenges: Avoiding Headaches and Delays](#troubleshooting-common-labeling-challenges-avoiding-headaches-and-delays)

- [The Road Ahead: Future Trends in Lithium Battery Labeling Technology](#the-road-ahead-future-trends-in-lithium-battery-labeling-technology)

- [How to Choose the Best Lithium Battery Label Printable Method for Your Needs](#how-to-choose-the-best-lithium-battery-label-printable-method-for-your-needs)

- [Common Pitfalls to Avoid When Dealing with Lithium Battery Labels](#common-pitfalls-to-avoid-when-dealing-with-lithium-battery-labels)

- [Advanced Tips for Experts: Optimizing Your Lithium Battery Labeling Workflow](#advanced-tips-for-experts-optimizing-your-lithium-battery-labeling-workflow)

- [Conclusion: Empowering Your Lithium Battery Journey with Confidence](#conclusion-empowering-your-lithium-battery-journey-with-confidence)

---

Understanding the "Why": The Critical Importance of Lithium Battery Labels

Before we dive into the "how-to" of "lithium battery label printable" solutions, let's truly grasp the fundamental "why." Why are these labels so important? It boils down to safety, legal compliance, and efficient logistics. Lithium batteries are energy-dense powerhouses, but this density also means they pose unique risks if not handled correctly. From thermal runaway (where a battery overheats and catches fire) to short circuits and dangerous fumes, the consequences of mishandling can be severe, impacting lives, property, and the environment.

- Preventing Accidents and Ensuring Safety: This is paramount. Labels are the first line of defense. They quickly communicate potential hazards to anyone handling the package – from warehouse staff to delivery drivers and even the end-user. Imagine a package containing a high-wattage battery mistakenly placed next to flammable materials. The right label immediately signals "handle with care, potential hazard." I once saw a small workshop fire caused by an unlabeled, damaged lithium battery pack that was simply tossed into a bin. It was a stark reminder that clear, visible warnings save lives and property.

- Adhering to National and International Regulations: The world of shipping and transport is governed by strict rules. Organizations like the International Air Transport Association (IATA) for air cargo, the International Maritime Dangerous Goods (IMDG) Code for sea freight, and the Department of Transportation (DOT) in the U.S. (along with similar bodies worldwide) mandate specific labeling for lithium batteries. Ignoring these regulations isn't just a slap on the wrist; it can lead to hefty fines, shipment delays, rejection of cargo, and even legal action. My aforementioned customs debacle was precisely because I underestimated the nuances of IATA's requirements for a specific battery type.

- Facilitating Emergency Response: In the unfortunate event of an incident – a fire, a spill, or a package breach – labels provide critical information for first responders. They tell emergency personnel what type of dangerous goods they are dealing with, guiding them on appropriate extinguishing methods, protective gear, and containment procedures. A clearly marked UN3480 label (Lithium Ion Batteries) tells firefighters to use specific non-water-based methods, which is crucial for safety.

- Streamlining Logistics and Supply Chains: Proper labeling isn't just about safety; it's about efficiency. When packages are correctly labeled, they move through the supply chain faster. Customs officials can quickly identify and clear compliant shipments, and carriers know exactly how to handle and stow them. Conversely, mislabeled or unlabeled packages cause bottlenecks, inspections, and delays, costing time and money. Think of it like a universal language for hazardous materials; everyone understands it, preventing miscommunication.

- Building Trust and Professionalism: For businesses, compliant and professional labeling reflects attention to detail and a commitment to safety. It builds trust with carriers, customers, and regulatory bodies. It shows that you understand the risks and are taking proactive steps to mitigate them. On the flip side, sloppy or incorrect labels can suggest negligence and erode confidence. When I finally got my labeling sorted after that customs issue, I received positive feedback from my logistics partner, which immediately boosted our working relationship. It's about demonstrating competence and responsibility.

Decoding the Details: Essential Types of Lithium Battery Labels You Can Print

The world of "lithium battery label printable" isn't a one-size-fits-all scenario. Different types of batteries, different shipping conditions, and different regulations demand specific labels. Understanding these distinctions is crucial for compliance. Here’s a breakdown of the most common and vital labels you'll encounter and why you might need to print them yourself.

- The Lithium Battery Mark (New for 2019/2020):

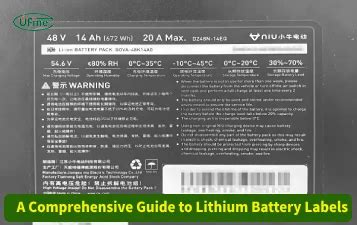

- What it is: This mark replaced the older Class 9 lithium battery hazard label for packages containing small lithium batteries (under 100 Wh for lithium-ion, 2g for lithium metal) shipped without other dangerous goods. It's identifiable by the battery symbol with a group of cells, a red diagonal border, and a white background.

- When you need it: Most commonly used for consumer electronics with batteries, or standalone batteries shipped in small quantities. If you're shipping a few spare drone batteries or a new smartphone, this is often the one. It signifies that the package contains lithium batteries and provides contact information for emergencies.

- Key information: Requires the UN number (UN3480 for lithium-ion, UN3090 for lithium metal), a phone number for additional information, and sometimes a statement about the type of battery.

- Printable advantage: Because the contact information changes per shipper, or if you're a small business, printing these yourself allows for customization and on-demand production, which is incredibly efficient. My team regularly prints these for individual customer orders.

- Class 9 Hazard Label (Miscellaneous Dangerous Goods):

- What it is: A diamond-shaped label with black stripes in the upper half and the number "9" in the bottom corner. It signifies "Miscellaneous Dangerous Goods."

- When you need it: Required for larger lithium battery shipments (over the limits for the Lithium Battery Mark), or when lithium batteries are shipped with other dangerous goods. It's a broader category that lithium batteries fall under due to their potential hazards.

- Key information: Does not include UN numbers directly on the label, but implies the presence of dangerous goods that require proper documentation (Shipper's Declaration of Dangerous Goods).

- Printable advantage: While the basic "9" label is standard, the ability to print it on demand means you always have the right quantity and size, especially if your shipping volume fluctuates.

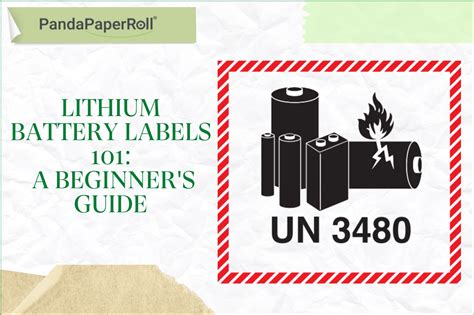

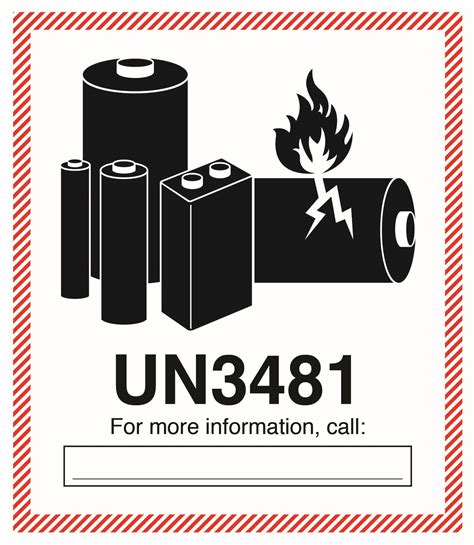

- UN Number Labels (UN3480, UN3481, UN3090, UN3091):

- What they are: These are specific four-digit codes assigned by the United Nations to classify hazardous materials.

- UN3480: Lithium Ion Batteries (standalone)

- UN3481: Lithium Ion Batteries contained in equipment or packed with equipment

- UN3090: Lithium Metal Batteries (standalone)

- UN3091: Lithium Metal Batteries contained in equipment or packed with equipment

- When you need them: These numbers must appear on the Class 9 label (if required) or adjacent to the Lithium Battery Mark, and always on the Shipper's Declaration. They tell carriers precisely what kind of lithium battery is inside. My most common need for printing UN numbers is alongside the Class 9 label for bulk shipments of standalone batteries.

- Key information: The specific UN number.

- Printable advantage: These are simple, text-based labels that are perfect for printing in-house, especially when you need to specify the exact UN number for varied shipments.

- Cargo Aircraft Only (CAO) Label:

- What it is: A rectangular label with "Cargo Aircraft Only" in bold red text, and an airplane symbol.

- When you need it: Required for certain lithium battery shipments that are prohibited from passenger aircraft and can only be transported by cargo aircraft. This applies to higher-risk configurations or larger quantities. If you're shipping a significant volume of standalone lithium-ion batteries, you'll likely need this.

- Key information: Clear warning that the package cannot go on passenger planes.

- Printable advantage: Essential for air freight, this label can be easily integrated into your "lithium battery label printable" workflow, ensuring you're always compliant with air cargo restrictions.

- Orientation Arrows (This Way Up):

- What they are: Two arrows pointing upwards, often within a square border.

- When you need them: Required for packages containing liquid substances or when the orientation of the package is critical for preventing leaks or damage, often applicable to batteries packed with electrolyte. While not always strictly *required* for lithium batteries themselves, they are often used as a best practice for packages containing equipment with batteries or certain types of battery packaging.

- Key information: Indicates the correct upright orientation of the package.

- Printable advantage: Simple, universal symbols that can be printed quickly for any package needing careful upright handling.

- "Damaged/Defective/Recalled" Lithium Battery Label:

- What it is: A specific warning label for batteries that are known to be damaged, defective, or subject to recall, indicating extreme caution. These require very specific handling and shipping protocols.

- When you need it: Crucial for returns, warranty claims, or disposal of faulty batteries. My company had to issue a recall once, and having the ability to print these specific, highly visible labels was critical for safe reverse logistics.

- Key information: Clear identification of the battery's compromised state.

- Printable advantage: These labels are less common but absolutely vital when needed, making in-house printing a lifesaver for rapid, compliant response.

- Temperature Control Labels:

- What they are: Labels indicating specific temperature ranges for storage or transport, sometimes with "Do Not Freeze" or "Keep Refrigerated" warnings.

- When you need them: While lithium batteries don't usually require refrigeration, extreme heat or cold can degrade performance or increase risk. For certain chemistries or sensitive electronics containing batteries, these might be necessary.

- Key information: Required temperature range.

- Printable advantage: If you're shipping sensitive battery packs for specialized applications (e.g., medical devices), being able to print these customized warnings is invaluable.

- GHS Hazard Pictograms:

- What they are: Globally Harmonized System (GHS) pictograms are standardized symbols that visually represent specific hazards (e.g., flammability, corrosivity, health hazards). While not always *directly* on the outer shipping package for standalone batteries, they are crucial for inner product labels or Safety Data Sheets (SDS).

- When you need them: Primarily for internal product labeling, SDS, or situations where the battery's internal components or chemistry pose additional, direct hazards beyond just "lithium battery."

- Key information: Visual warning of specific hazards.

- Printable advantage: Useful for manufacturers or those creating their own battery packs who need to ensure internal components are also clearly labeled according to GHS standards.

- Custom Internal Labels (e.g., QC, Serial Number, Date Code):

- What they are: Labels used for internal tracking, quality control, or product identification, often placed directly on the battery cell or pack.

- When you need them: Essential for manufacturers, assemblers, or even hobbyists who want to keep detailed records of their battery packs. I always print custom internal labels with build dates and specific cell batches for my custom packs; it saves so much headache during troubleshooting or warranty claims.

- Key information: Serial numbers, manufacturing dates, QC checks, internal part numbers.

- Printable advantage: Total flexibility in design and content, crucial for inventory management and quality assurance.

- Destination/Recipient Information Labels:

- What they are: Standard shipping labels with recipient address, sender address, tracking numbers, and sometimes carrier-specific barcodes.

- When you need them: For every shipment! While not strictly "lithium battery labels," they are an integral part of the overall package labeling.

- Key information: Who, what, where, when.

- Printable advantage: Most shipping software integrates with label printers, making this a seamless part of your "lithium battery label printable" workflow.

DIY vs. Pro: Choosing Your Lithium Battery Label Printable Solution

When it comes to getting those crucial "lithium battery label printable" on your packages, you essentially have two main paths: doing it yourself (DIY) or outsourcing to professional label printers. Both have their merits, and the best choice often depends on your volume, budget, and specific needs.

### DIY Lithium Battery Label Printing

This is where you take control, printing labels in-house using your own equipment.

- Pros:

- Cost-Effectiveness for Low Volume: If you're shipping a few battery packs a week or month, printing on demand is incredibly cheap. You only print what you need, reducing waste and bulk inventory of pre-printed labels.

- Flexibility and Customization: Need a UN number changed? A new phone number for emergencies? A specific internal tracking code? DIY allows for instant modifications. This flexibility is what saved me during my customs incident; I could immediately print the corrected labels without waiting for an external vendor.

- Immediate Availability: No waiting for orders to be processed, printed, and shipped back to you. When you need a label, you print it. This is invaluable for urgent shipments or unexpected changes in regulations.

- Control Over Quality (to an extent): You choose the label stock, the printer, and the ink. You can ensure the labels are durable and readable.

- Learning Opportunity: It forces you to understand the regulations better, as you are directly responsible for generating compliant labels.

- Cons:

- Upfront Investment: You'll need a suitable printer (thermal transfer is often recommended for durability), label stock, and potentially design software.

- Time Commitment: Designing, proofing, and printing labels takes time, especially if you have varying requirements.

- Potential for Error: Without automated systems or expert knowledge, the risk of printing incorrect or non-compliant labels is higher. One misplaced digit in a UN number can cause major headaches.

- Scalability Challenges: If your volume suddenly skyrockets, your in-house setup might struggle to keep up, leading to bottlenecks and increased labor costs.

- Quality Consistency: Achieving professional-grade print quality consistently can be challenging without high-end equipment and proper calibration.

### Professional Label Printing Services

This involves outsourcing your label needs to companies specializing in printing hazardous materials labels.

- Pros:

- Guaranteed Compliance: Reputable professional printers are experts in hazmat labeling. They often stay updated on the latest regulations, ensuring your labels are compliant. This is a huge load off your mind, especially for complex international shipments.

- High-Quality, Durable Labels: Professionals use industrial-grade printers and materials, resulting in extremely durable, weather-resistant, and high-resolution labels. They often have access to specialized adhesives for challenging surfaces.

- Scalability: They can handle large volumes with ease, providing consistent quality whether you need 100 or 100,000 labels.

- Reduced Labor and Time: You simply provide the specifications, and they deliver the finished labels, freeing up your internal resources.

- Cost-Effectiveness for High Volume: For very large orders, the per-label cost from a professional printer can often be lower than what you could achieve in-house, especially considering material waste and labor.

- Cons:

- Higher Cost for Low Volume: Minimum order quantities and setup fees can make professional printing uneconomical for small batches.

- Lead Times: You have to plan ahead. There's a waiting period for design, printing, and shipping, which can be an issue for urgent needs.

- Less Flexibility: Changes require re-ordering, which incurs additional costs and delays. If a regulation changes slightly, you might be stuck with a batch of outdated labels.

- Less Control: You're reliant on their processes and quality control.

### Which Path is Right for You?

- For Beginners or Low Volume (Hobbyists, Small Etsy Shops): DIY "lithium battery label printable" is often the most sensible choice. Invest in a good desktop thermal printer, some durable label stock, and familiarize yourself with the basic regulations. This gives you maximum flexibility and cost control. My personal setup started exactly here.

- For Medium Volume (Growing E-commerce, Small Manufacturers): A hybrid approach might be best. Print common, high-volume labels (like the Lithium Battery Mark) in-house for speed and flexibility, but outsource specialized or very large runs (like Class 9 labels for thousands of identical products) to professionals for compliance assurance and quality.

- For High Volume (Large Manufacturers, Distributors, Logistics Companies): Professional printing is almost certainly the way to go for the bulk of your needs, especially for critical compliance labels. You can still maintain a small in-house "lithium battery label printable" setup for urgent, small-batch, or highly customized needs.

Ultimately, the decision balances cost, control, compliance assurance, and volume. Don't be afraid to start DIY and scale up or integrate professional services as your needs evolve.

Navigating the Maze: Compliance for Different Modes of Transport and Industries

This is arguably the most complex aspect of "lithium battery label printable" – understanding that regulations aren't universal. What's perfectly fine for ground shipping in one country might get your package seized at an airport in another. The key is to know which regulations apply to *your* specific situation.

- Air Transport (IATA Dangerous Goods Regulations - DGR):

- The Gold Standard of Strictness: Air transport is the most restrictive due to the catastrophic potential of in-flight fires. IATA DGR is the bible for air cargo.

- Key Differences:

- Packaging Instructions (P.I.): IATA specifies detailed packaging instructions (e.g., P.I. 965 for standalone lithium ion batteries, P.I. 966 for those packed with equipment, P.I. 967 for those contained in equipment). Each P.I. has specific labeling requirements, including the Lithium Battery Mark or Class 9 label, UN numbers, and sometimes Cargo Aircraft Only.

- State and Operator Variations: Individual countries (states) and airlines (operators) can impose additional restrictions beyond IATA DGR. Always check the "State and Operator Variations" section of the DGR manual. This is where I got caught out once; a specific airline had a stricter rule on a certain battery size than IATA generally mandated.

- Watt-Hour (Wh) Limits: Very strict limits on the Watt-hour rating of batteries that can be shipped on passenger aircraft, and even on cargo aircraft.

- Printable Implications: You must be able to print the correct Lithium Battery Mark (with your contact info), Class 9 label, UN numbers, and often the Cargo Aircraft Only label, precisely to IATA specifications.

- Sea Transport (IMDG Code - International Maritime Dangerous Goods):

- Less Restrictive, Still Critical: While generally less restrictive than air transport, IMDG is still highly regulated due to the potential for long voyages and large quantities.

- Key Differences:

- Container Labeling: Requirements often extend to the container itself, not just individual packages.

- Stowage Categories: IMDG assigns stowage categories (e.g., "away from heat") that affect where the container can be placed on a ship.

- Emergency Response Information: More emphasis on detailed emergency response information for onboard personnel.

- Printable Implications: You'll likely need Class 9 labels, UN numbers, and potentially orientation arrows. Durability of the label is paramount due to harsh marine environments.

- Road Transport (ADR in Europe, DOT 49 CFR in U.S., TDG in Canada):

- Regional Regulations: Ground transport regulations are often specific to regions or countries.

- U.S. (DOT 49 CFR): Governs hazardous materials transport by highway, rail, and air. It aligns closely with international standards but has its own specific nuances for domestic shipments.

- Europe (ADR): The European Agreement concerning the International Carriage of Dangerous Goods by Road.

- Canada (TDG): Transport of Dangerous Goods Regulations.

- Key Differences:

- Small Quantity Exceptions: Often more generous exceptions for "small quantities" of lithium batteries compared to air transport, simplifying labeling for consumer products.

- Placarding: For larger quantities, vehicle placarding (large diamond signs on the outside of the truck/trailer) becomes a requirement.

- Printable Implications: For smaller shipments, the Lithium Battery Mark and UN numbers are common. For larger shipments, you might need to coordinate with carriers for appropriate placarding. Having a versatile "lithium battery label printable" setup allows you to quickly adapt to different regional requirements.

- Rail Transport:

- Often aligns closely with road transport regulations (e.g., DOT 49 CFR in the U.S., RID in Europe). Similar labeling principles apply.

- Industry-Specific Needs:

- Manufacturing: Internal QC labels, batch numbers, GHS pictograms for internal handling.

- Recycling/Disposal: Specific labels for "damaged/defective/recalled" batteries, often requiring specialized packaging and transport.

- Retail/E-commerce: Focus on consumer-friendly packaging and compliance with general shipping regulations for small quantities.

- Aerospace/Defense: Extremely stringent requirements, often involving custom internal labels and highly robust external labels.

The Golden Rule: Always consult the latest version of the relevant regulations for your specific mode of transport and destination. Don't rely on outdated information or assumptions. When in doubt, contact your carrier or a hazmat consultant. My personal mantra is: "If I'm not 100% sure, I'm not shipping it until I am." This diligence, supported by my versatile "lithium battery label printable" system, has saved me from repeated customs nightmares.

Designing Your Own: Unleashing Creativity (Within Compliance) for Printable Labels

The phrase "designing your own" might conjure images of elaborate graphics, but for "lithium battery label printable" solutions, creativity lies in efficiency, clarity, and precision *within* strict regulatory boundaries. This isn't about artistic flair; it's about making essential information instantly recognizable and compliant.

- Mastering the Regulatory Templates:

- The Foundation: Start with official templates provided by IATA, IMDG, DOT, or reputable hazmat label suppliers. These templates ensure correct dimensions, colors (e.g., red border for the Lithium Battery Mark, black stripes for Class 9), symbols, and font sizes. Don't try to reinvent the wheel here; compliance is non-negotiable.

- Example: For the Lithium Battery Mark, ensure the minimum dimensions (120x110mm for packages large enough to accommodate it, otherwise 100x70mm) are met, the red border is exactly 5mm wide, and the battery symbol is correctly placed.

- Hypothetical Scenario: I once tried to save space by slightly reducing the margin on a Class 9 label. My logistics partner immediately flagged it, explaining that exact dimensions are part of the compliance. Lesson learned: stick to the templates rigorously.

- Integrating Variable Data (UN Numbers, Phone Numbers, etc.):

- Dynamic Information: This is where the "printable" aspect truly shines. Labels for lithium batteries almost always require variable data:

- UN Number: (e.g., UN3480, UN3481)

- Emergency Contact Phone Number: Your company's 24-hour emergency number.

- Shipper's Name/Address: For identification.

- Watt-hour (Wh) Rating or Grams of Lithium: Required for certain documentation or internal labels.

- Design Tip: Create a base template for each label type in your software (e.g., Adobe Illustrator, BarTender, even Microsoft Word/Excel for simple ones) with placeholders for this variable data. This allows you to quickly input the correct information for each shipment.

- Personal Scenario: When shipping different models of e-bike batteries, each with a slightly different Wh rating, I use a template that dynamically pulls the correct UN number and Wh from my inventory database. This eliminates manual entry errors.

- Choosing the Right Software for Design:

- Basic Needs: For simple, repetitive labels, even Microsoft Word or Google Docs can work if you accurately set up page sizes and print to templates.

- Intermediate: Dedicated label design software like BarTender, NiceLabel, or ZebraDesigner (often free with Zebra printers) offer much more control, database integration, and pre-built hazmat templates. These are excellent for managing varying data.

- Advanced: Graphic design software (Adobe Illustrator, CorelDRAW) gives you ultimate control but has a steeper learning curve and is usually overkill unless you're designing custom internal branding *around* the compliant elements.

- Subjective Tip: Personally, I prefer BarTender for its robust database integration and vast library of compliance symbols. It makes generating thousands of unique, compliant labels a breeze.

- Material Selection and Durability:

- Paper vs. Synthetic: While basic paper labels might suffice for internal use, shipping labels, especially for dangerous goods, need to be durable.

- Paper: Economical, easy to print, but vulnerable to moisture and abrasion.

- Polypropylene/Polyester (Synthetic): Highly recommended. These are tear-resistant, water-resistant, and can withstand harsher environmental conditions. Thermal transfer printing on these is ideal for longevity.

- Adhesive: Ensure the adhesive is strong enough for your packaging material (cardboard, plastic, metal) and will not degrade or peel off during transit, especially in varying temperatures.

- Print Quality: Ensure your printer (and ribbon for thermal transfer) produces crisp, smudge-proof prints that remain legible throughout the journey. A faded or smeared label is as useless as no label at all.

- Strategic Placement and Visibility:

- Clear View: Labels must be placed on a contrasting background, on a surface that is not obscured by other labels, tape, or packaging features.

- Multiple Sides: For larger packages, consider placing labels on at least two perpendicular sides to ensure visibility from different angles.

- No Creases: Avoid placing labels over seams, edges, or areas that will crease or tear easily.

- Personal Anecdote: I once received a package where the Class 9 label was partially obscured by shipping tape. It immediately raised a red flag for me, reinforcing the need for careful application. Treat every label as a critical piece of communication.

By focusing on regulatory accuracy, leveraging software for efficiency, choosing durable materials, and ensuring proper placement, you can effectively "design" and print your own lithium battery labels with confidence and compliance.

Tools of the Trade: Software and Equipment for Your Printable Lithium Battery Labels

Having the right "lithium battery label printable" tools makes all the difference in efficiency, accuracy, and compliance. This isn't just about owning a printer; it's about setting up an ecosystem that supports your labeling needs.

### 1. The Right Printer

- Thermal Transfer Printers (Highly Recommended):

- Why: These use a heated printhead to transfer ink from a ribbon onto the label material. The result is extremely durable, long-lasting prints that resist smudging, fading, moisture, and abrasion – critical for hazardous materials labels that must remain legible throughout transit.

- Brands: Zebra, Sato, Honeywell, TSC are industry leaders.

- Example: A Zebra ZT411 or a smaller desktop model like the Zebra ZD421 (my personal go-to for medium volume) are excellent choices. They handle various label sizes and materials.

- Personal Experience: I initially tried a standard inkjet for labels and quickly learned my lesson. The ink smudged, faded in humidity, and peeled. Switching to thermal transfer was a game-changer for durability and reliability.

- **Direct Thermal Printers (