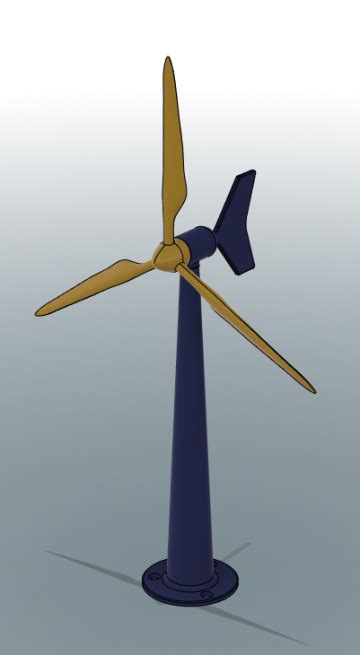

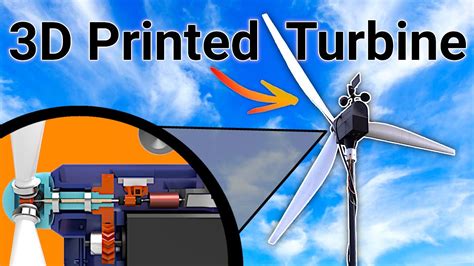

Have you ever looked at a gust of wind and wished you could bottle that energy, perhaps to power something small and meaningful? Trust me, you’ve been there. I remember the first time I saw a truly well-designed 3D printable wind turbine in action – a tiny beacon spinning against the sky, generating a flicker of light. It sparked something in me, a mix of awe and pure, unadulterated "I have to build that!" excitement. But let me tell you, what seems simple in a CAD model can present its own unique challenges in the real world. This journey isn't just about printing parts; it's about understanding how to harness the invisible, turning raw filament into tangible, sustainable power.

Whether you're a seasoned maker looking for your next challenge, a curious beginner stepping into the fascinating world of renewable energy, or just someone fascinated by the intersection of DIY and green tech, you’re in the right place. We're going to dive deep into everything you need to know about 3D printable wind turbines – from the fundamental "whys" to the nitty-gritty of design and assembly, ensuring you avoid the pitfalls I learned the hard way.

Why Even Bother? The Allure of DIY Wind Power

So, why invest your precious filament and time in a 3D printable wind turbine? It's more than just a cool gadget; it’s a hands-on foray into sustainable energy and a fantastic learning experience. From tiny phone chargers to educational models for classrooms, the possibilities are surprisingly vast for these micro wind power devices.

- Learning by Doing: There’s no better way to understand aerodynamics, energy conversion, and basic electronics than by building something yourself. It makes abstract concepts tangible.

- Sustainable Hobby: You’re not just consuming; you’re creating something that potentially generates clean energy. It's a small step towards a more sustainable future, right from your desktop.

- Off-Grid Potential (Small Scale): While they won't power your entire home, these turbines can charge batteries for camping, emergency lights, or even small remote sensors. I once used a tiny setup to power a weather station at the back of my yard, far from any outlets!

- Customization & Innovation: Unlike off-the-shelf solutions, you have complete control over design, materials, and modifications. Want to experiment with a new blade shape? Go for it! This flexibility is truly what makes 3D printing for renewable energy so exciting.

Your First Spin: Getting Started with 3D Printable Wind Turbines

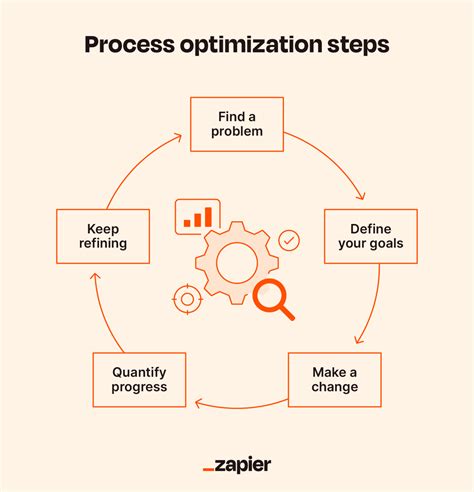

If you’re new to this, the thought of designing and printing a wind turbine might seem daunting. But fear not! Breaking it down makes it much more manageable. Think of it as a journey, not a sprint.

- The Right Printer & Filament: While many FDM printers can handle this, a well-calibrated machine is key. PLA is a common starting point due to its ease of use, but consider PETG or ABS for outdoor durability if you plan on deploying it outside. Trust me, you don't want your beautifully printed blades warping in the sun!

- Finding Your First Design (STL Files): The internet is brimming with free STL files for various wind turbine designs – from classic horizontal axis (HAWT) to more futuristic vertical axis (VAWT) models. Sites like Thingiverse and Printables.com are fantastic resources. Don't be afraid to start with a simple, proven design to get a feel for the process.

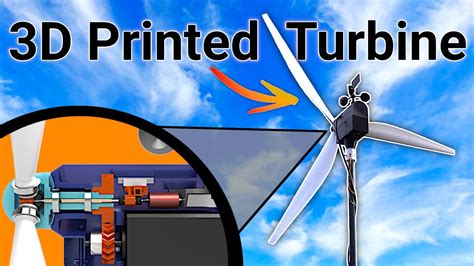

- Beyond the Plastic: Essential Components: Remember, a turbine isn't just plastic. You'll need a small generator (often a repurposed DC motor), wiring, possibly a rectifier, and a way to mount it. Think small electronics, not just 3D models.

- Safety First: We're dealing with spinning parts and electricity, however small. Always ensure blades are securely attached and wiring is properly insulated. A little caution goes a long way.

Designing for the Breeze: Types & Optimization Tips

The heart of any wind turbine is its design, especially the blades. This is where the magic of aerodynamics meets the practicality of 3D printing. Understanding basic principles will dramatically improve your turbine's performance.

- Horizontal Axis Wind Turbines (HAWT): These are what most people picture – propeller-like blades facing the wind. They are generally more efficient for larger power generation but require a mechanism to yaw (turn into the wind).

- Vertical Axis Wind Turbines (VAWT): Savonius and Darrieus designs are common VAWTs. They catch wind from any direction, making them easier to deploy, though often less efficient for the same swept area. My personal preference is often VAWTs for small, experimental projects because they are so much easier to set up without complex yaw mechanisms.

- Blade Profile & Pitch: The shape (airfoil) and angle (pitch) of your blades are crucial. A well-designed airfoil will generate more lift, capturing more energy. Experiment with different pitches in your slicer software for small adjustments; even a degree or two can make a difference.

- Infill & Wall Thickness: For strong, durable blades that can withstand rotation, increase infill percentage and wall thickness. You'll thank yourself when your turbine is humming along instead of shattering.

- Balancing Your Blades: An unbalanced rotor will wobble, make noise, and wear out components faster. Take the time to balance your printed blades by adding small weights (like tiny pieces of tape or glue) until it spins smoothly. I once skipped this step, and my turbine shook itself right off its mount!

Bringing It to Life: Printing & Assembly Know-How

You've got your design, your filament, and your printer ready. Now for the tactile satisfaction of watching your project come together.

- Slicer Settings for Success: Optimize print speed, layer height, and support structures. For smooth blade surfaces that catch the wind efficiently, lower layer heights (e.g., 0.12mm-0.2mm) are often recommended. Consider "fuzzy skin" for blade texture in some experimental designs!

- Post-Processing for Performance: Sanding and smoothing blades can reduce drag and improve efficiency. Don't underestimate the power of a little sandpaper and elbow grease to truly optimize your efficient wind turbine design.

- Connecting the Dots (Wiring): This is where your tiny turbine generates power. Connect your DC motor (now acting as a generator) to a bridge rectifier (to convert AC/pulsating DC to smooth DC), then to a capacitor and perhaps a small load like an LED or battery charging circuit.

- Mounting it Right: Whether on a pole, a sturdy frame, or a desktop stand, ensure your turbine is securely mounted and can freely rotate (if HAWT). Stability prevents vibration and damage.

Powering the Small Stuff: Real-World Applications

So, you’ve built your miniature marvel. What can it actually do? These small-scale wind power generators are perfect for numerous low-power applications, acting as a testament to your home energy generation skills.

- Charging Small Devices: Think USB power banks, smartphones (slowly!), or small IoT devices. Many makers use them to trickle-charge batteries.

- Outdoor Lighting: Power an LED garden light or a small emergency lamp for camping.

- Educational Demonstrations: They are fantastic tools for teaching kids (and adults!) about renewable energy, physics, and engineering principles.

- Remote Sensors: Powering weather stations, environmental monitors, or security cameras in areas without easy access to grid power. I know a friend who uses one for his remote bird feeder camera – super cool!

When the Wind Won't Spin: Troubleshooting & Tweaks

It's rare for a project to work perfectly the first time. Here's what I've learned about common snags and how to overcome them. Don’t be like me and spend hours staring at a stationary turbine wondering "what gives?" when it's something simple!

- No Spin? Check for Friction: Ensure all bearings and moving parts spin freely. Is there anything rubbing? Is your shaft perfectly straight?

- Low Power Output: Are your blades optimized for your wind conditions? Is your generator efficient enough? Sometimes, simply changing the propeller to a different pitch or increasing the number of blades can yield surprising results. Also, ensure your generator isn't creating too much resistance.

- Wobbling & Vibrations: This usually points to unbalanced blades or an unstable mounting. Re-balance your blades carefully and reinforce your mounting structure.

- Filament Failure: If blades are breaking, consider a stronger material like ABS or ASA, or increase infill and wall thickness. Print quality can also be a factor; poor layer adhesion will weaken parts.

- Wind Direction Challenges (HAWT): If your HAWT isn't turning into the wind, check your tail fin design and make sure the pivot point is frictionless.

The Future on the Horizon: Advanced & Beyond

Once you've mastered the basics, the world of 3D printable wind turbine innovation opens up even further. This isn't just a fleeting trend; it's part of a broader movement towards accessible, decentralized energy.

- Smart Turbines: Integrating microcontrollers like Arduinos or ESP32s to monitor wind speed, power output, and even adjust blade pitch dynamically for optimal performance.

- Grid Tie-Ins (for the bold): For advanced users, connecting small turbine arrays to charge larger battery banks or even integrate with a micro-grid system (always with proper safety and electrical expertise!).

- Hybrid Systems: Combining your wind turbine with small solar panels for a truly resilient DIY renewable energy system that works day and night.

- New Materials & Techniques: Experimenting with composite materials, multi-material printing, or even flexible filaments for different blade designs.

Tips for Personalizing Your Wind Turbine Project

Building a 3D printed wind turbine is incredibly rewarding, and making it uniquely yours amplifies that satisfaction.

- Tailor to Your Wind Conditions: Don't just print any design. Research average wind speeds in your location and choose a blade design optimized for those conditions. A turbine designed for strong winds won't perform well in light breezes, and vice-versa.

- Consider Your Power Needs: Are you charging an LED, a phone, or just demonstrating? This dictates the size and complexity of the generator you'll need.

- Aesthetics Matter: While functionality is key, don't shy away from adding your personal touch. Different filament colors, custom bases, or even integrating it into a garden sculpture can make your project truly stand out. I find that a splash of bright color on the blades really makes them pop when spinning!

- Document Your Journey: Keep notes, take photos, and share your progress! The maker community thrives on shared knowledge and overcoming challenges together.

Common Pitfalls: What to AVOID When Building 3D Printed Wind Turbines

Nobody wants to make avoidable mistakes. Learn from the collective experience (and a few of my own embarrassing moments!).

- Don't Overestimate Output: A small 3D printed turbine isn't going to power your refrigerator. Manage your expectations about the power it will generate. It's for small loads or educational purposes.

- Ignoring Aerodynamics: Simply making a blade shape that "looks right" won't cut it. Basic understanding of airfoils and pitch makes a world of difference. Your turbine won't just "catch the wind"; it needs to *channel* it efficiently.

- Using Too Weak or Too Brittle Filament: PLA is great for prototypes, but outdoor exposure and continuous rotation demand tougher materials like PETG, ABS, or even ASA. Don’t be like me and have your turbine's blades snap off in the middle of a windy day because I skimped on material!

- Poorly Sourced Components: Cheap, low-quality DC motors used as generators can be inefficient or fail quickly. Invest a little more in decent components; it pays off in the long run.

- Skipping Safety Checks: Double-check all wiring, ensure blades are securely mounted, and never leave an experimental setup unattended without proper safeguards, especially if charging batteries.

- Giving Up Too Soon: Troubleshooting is part of the fun! Every problem is an opportunity to learn. Don't let a stalled rotor or low voltage dampen your enthusiasm.

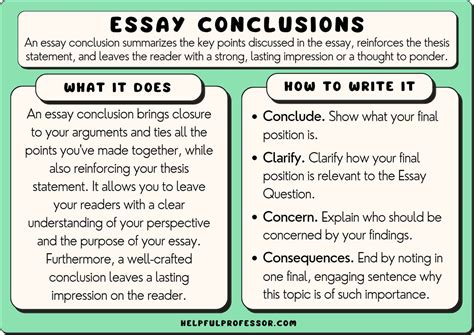

Conclusion

Stepping into the world of 3D printable wind turbines is an incredibly empowering journey. It's a chance to connect with fundamental engineering principles, contribute to a more sustainable mindset, and create something truly unique with your own hands. From the first click of the print button to the satisfying hum of a spinning rotor, every step is a learning experience. Now go forth, embrace the wind, and let your creativity take flight – or rather, make your blades spin!