There’s nothing quite like the rush of whitewater, the spray on your face, the roar of the river. But let’s be honest, sometimes our gear takes a beating. And finding that *exact* replacement part, or a custom solution that truly fits your style, can feel like searching for a needle in a haystack. I’ve been there – standing on the bank, watching a small, easily replaceable part float downstream after a particularly enthusiastic eddy line, thinking, “There *has* to be a better way.” Well, fellow river rats, there is: 3D printing.

Gone are the days when custom whitewater parts were reserved for the pros or those with deep pockets. With a home 3D printer, the power to create, repair, and personalize your rafting setup is literally at your fingertips. From essential upgrades to clever emergency fixes, understanding the potential of 3d printable rafting whitewater parts can revolutionize your river experience. This isn't just about saving a few bucks; it’s about unlocking a new level of customization and self-reliance on the water.

Essential Gear & Accessory Upgrades You Can Print

Let’s start with the basics – those everyday components that take a beating or just aren't quite right. Having the ability to print these vital 3d printable rafting whitewater parts ensures you’re always prepared.

- Custom D-Rings & Attachment Points: While not for structural integrity where life depends on it, sturdy D-rings for gear attachment or securing small items can be printed. Focus on strong infill and durable materials.

- Paddle Clips & Oar Stops: A common culprit for breaking. Design these to perfectly fit your paddle shaft or oar, often outperforming generic store-bought ones. I once printed a set of custom paddle clips that fit my unique shaft profile better than any commercial clip, ensuring my paddle was always secure, even in turbulent water.

- Drain Plugs & Valves: Lost a drain plug? No problem. Measure your existing one (or the hole!) and print a new, watertight version. I’ve personally printed custom drain plugs for my old raft, and they fit better than any store-bought ones, saving me from a leaky afternoon on the Arkansas River.

- Grab Handles & Loops (Non-Load Bearing): For lighter duty use, such as pulling a kayak onto shore or as additional anchor points for light gear.

- Safety Whistle & Compass Holders: Securely attach these crucial safety items right where you need them on your PFD or raft frame.

Custom Comfort & Ergonomic Solutions

Why settle for generic when you can have gear molded to *you*? These 3d printable rafting whitewater parts focus on making your time on the water more comfortable and efficient.

- Custom Seat Adjustments & Shims: Fine-tune your seating position for optimal paddling posture and reduced fatigue. If your seat is a little wobbly, a custom shim can make all the difference.

- Personalized Paddle Grips: Tired of blisters or an awkward grip? Design ergonomic grips that perfectly fit your hands. My buddy, who always complained about his feet slipping, designed custom foot pegs that locked his boots in place. He credits them with keeping him in the boat during a gnarly flip.

- Knee Pads & Thigh Straps Adapters: For those in inflatable kayaks or duckies, custom-fit knee pads or adapters for existing thigh straps can significantly improve control and comfort.

- Foot Braces/Pegs: Create inserts or attachable pegs that give you a solid brace point against the boat, improving your power transfer with each stroke.

- Water Bottle or Gear Tethers: Simple, custom loops to keep essential items from floating away.

Repair & Emergency Fixes on the Fly

Sometimes, disaster strikes. Having the knowledge (and pre-printed parts!) for emergency fixes can be a trip-saver. These 3d printable rafting whitewater parts are about preparedness.

- Hose Connectors & Adapters: For pump hoses, water bladders, or even fuel lines on motorized rafts. A small, pre-printed hose coupler saved our trip once when a pump hose cracked miles from the put-in – a lesson learned the hard way about being prepared!

- Small Buckle Replacements: While not for critical load-bearing straps, a quick-release buckle for a dry bag or secondary attachment can save the day.

- Patch Clamps/Reinforcements: Small, rigid frames that can be placed over a minor tear in conjunction with tenacious tape or adhesive to provide a temporary, stronger seal.

- Clever Cable Management Clips: Keep your ropes, safety lines, or even charging cables tidy and untangled, preventing potential hazards.

- Go-Pro or Accessory Latch Replacements: If a small plastic latch breaks on an accessory, a 3D printed replacement can quickly get you back to filming the action.

Mounts, Holders & Integration Tools

Capture the adventure or keep your navigation tools handy. These 3d printable rafting whitewater parts help integrate your tech and accessories seamlessly.

- Camera Mounts (Non-Structural): Design custom mounts for action cameras (GoPro, Insta360) that securely attach to your raft frame, paddle, or helmet. My custom GoPro mount, printed specifically for my raft's frame, gave me incredible footage from angles I could never achieve with off-the-shelf clamps. Just make sure to tether it, trust me – the river doesn't care how good your footage is if your camera is at the bottom of it!

- GPS/Fish Finder Holders: Securely mount your navigation or fishing electronics in an accessible, visible spot.

- Dry Bag Anchors/Clips: Create custom clips that integrate with your raft’s existing D-rings or webbing to keep dry bags precisely where you want them.

- Drink Holders: Because staying hydrated is crucial, and a custom holder ensures your beverage is always within reach and won't tip over.

- Utility Hooks/Carabiner Holders: Small, handy hooks to clip various items, preventing them from rolling around the boat.

Performance-Enhancing Prototypes & Experimental Designs

For the truly adventurous and design-savvy, 3D printing opens the door to experimenting with performance. These 3d printable rafting whitewater parts are where innovation meets the current.

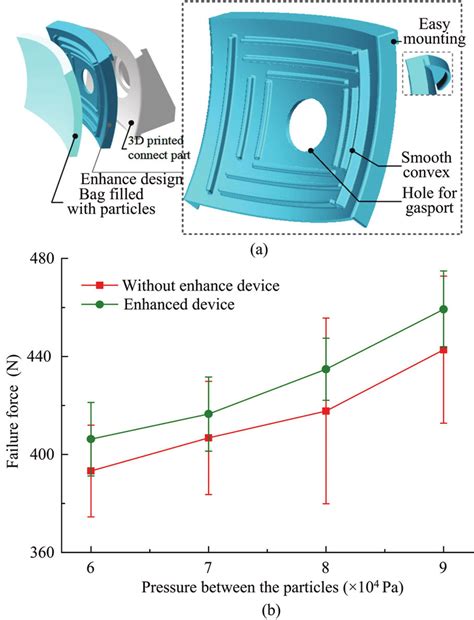

- Custom Skegs/Fins (for inflatables): Experiment with different fin shapes and sizes to improve tracking and stability on inflatable kayaks or smaller rafts. Experimenting with a small, 3D-printed skeg on my inflatable kayak helped with tracking in flat sections, a project that literally took my paddling to the next level without costly modifications.

- Paddle Blade Protectors/Tips: While you wouldn't print a whole blade, small, sacrificial tips can protect your expensive paddle from rock scrapes.

- Oar Lock Bushings/Inserts: For older oar locks with a bit of play, printing custom bushings can tighten them up, improving your rowing efficiency.

- Aerodynamic Frame Covers (for racing): For the competitive types, subtle covers for frame sections might reduce drag (though the effect might be minimal, the fun is in the attempt!).

- Bailer Enhancements: Design improved grips or even small scoops for your bailer to make the job quicker.

Material Deep Dive: Choosing the Right Filament for the River

This is where the rubber (or rather, the plastic) meets the road. The material choice is paramount for 3d printable rafting whitewater parts, ensuring durability, safety, and longevity.

- PETG (Polyethylene Terephthalate Glycol): My personal go-to for many rafting parts. PETG is known for its excellent water resistance, good strength, and decent UV resistance. It's less brittle than PLA but easier to print than ABS. For me, PETG is the unsung hero of outdoor prints – it just holds up!

- ASA (Acrylonitrile Styrene Acrylate): Often considered the successor to ABS, ASA boasts superior UV resistance, making it ideal for parts constantly exposed to sunlight. It's strong and weather-resistant, perfect for external raft components.

- ABS (Acrylonitrile Butadiene Styrene): Strong and somewhat flexible, but notoriously difficult to print without warping. While durable, its poor UV resistance means it degrades in sunlight unless treated or painted. I learned quickly that PLA is a no-go for anything exposed to the sun or stress. My first 'clever' paddle clip melted into a sad, droopy mess on a hot day – definitely a 'don’t be like me' moment!

- TPU (Thermoplastic Polyurethane): The king of flexibility. Ideal for bumpers, flexible seals, anti-slip pads, or anything that needs to bend and absorb impact. It’s also very abrasion-resistant.

- Nylon/Carbon Fiber Composites: For high-strength, low-weight applications where rigidity is key. These require advanced printing setups (enclosures, high-temp nozzles) but offer exceptional performance for structural or high-stress parts.

Key Considerations for Materials:

- UV Resistance: Crucial for anything exposed to the sun.

- Water Resistance: Essential to prevent material degradation.

- Impact Resistance: Whitewater is rough; parts need to withstand bumps and scrapes.

- Temperature Tolerance: Parts left in the sun can reach high temperatures.

- Layer Adhesion: Strong layer adhesion is vital for robust parts.

Designing Your Own: From Idea to River-Ready Print

For those with a knack for design, the real magic happens when you create your own 3d printable rafting whitewater parts from scratch.

- Learn a CAD Software: Free options like Fusion 360 or Tinkercad are great starting points. Tinkercad is fantastic for beginners, while Fusion 360 offers more professional features for complex designs.

- Design for Strength: Think about infill (100% for critical parts!), wall thickness, and print orientation to maximize strength along stress lines. Don't underestimate the power of fillets and chamfers to distribute stress!

- Consider Post-Processing: Will your part need sanding, painting, or sealing? Design with that in mind.

- Prototype and Test: Print multiple iterations. Test them in non-critical environments first. Submerge them, leave them in the sun, put them under stress.

- Embrace Iteration: The most satisfying part is seeing your own design go from a screen to a functional part. I spent weeks refining a unique oar stop, and when it finally held up perfectly on a multi-day trip, it felt like a true accomplishment. Don't be afraid to fail; each failed print is a lesson learned.

Tips for Personalizing Your Rafting Gear

Making your gear truly *yours* goes beyond just functionality. Here’s how to add that personal touch.

- Consider Your Specific Raft/Kayak Model: Measure twice, print once. Custom fittings will always outperform generic ones.

- Think About Your Personal Paddling Style: Do you prefer aggressive or relaxed? Your gear can reflect that.

- Integrate Multi-Functional Designs: Can your camera mount also hold a small light? Can your drain plug have a built-in tether point?

- Add Unique Colors or Textures: Express your personality with filament colors or by incorporating custom textures into your designs.

- Start Simple: I find that starting with a simple, non-critical part (like a custom water bottle holder or a decorative cap) is the best way to get a feel for what works before tackling something structural or safety-critical. This builds confidence and understanding of your materials.

Common Pitfalls: What to AVOID When 3D Printing Whitewater Parts

Even experts make mistakes. Learning from them (or avoiding them entirely!) is key to successful 3d printable rafting whitewater parts.

- Ignoring Material Properties: Don't use PLA for anything that will see sun, heat, or significant stress. It will degrade, deform, and potentially fail at the worst possible moment. The river doesn't care how cool your 3D print looks if it fails. Always, *always* prioritize safety over a clever hack.

- Under-Engineering Your Parts: Don't skimp on infill or wall thickness for critical components. A hollow or flimsy print won't stand a chance against whitewater forces.

- Forgetting Post-Processing: Many parts benefit from sanding (to smooth rough edges), sealing (especially for watertight applications), or painting (for UV protection on non-UV resistant materials).

- Neglecting Safety: Never print structural parts that could lead to injury or fatality if they fail. This includes load-bearing frame components, critical tie-downs, or paddle shafts. Buy these from reputable manufacturers. 3D printing is fantastic for accessories and repairs, not life-support. Don't be that person explaining why their oar went rogue because of a faulty print in a Class IV rapid!

- Not Testing Thoroughly: Don’t just print and go. Test your parts under realistic conditions before relying on them in a remote river canyon.

Conclusion

The world of 3d printable rafting whitewater parts is an exciting frontier for any river enthusiast who loves to tinker, customize, and innovate. It empowers you to fix, upgrade, and personalize your gear in ways previously impossible. While safety must always be paramount – remember, some things are just better bought – the potential for customization, repair, and creative problem-solving is immense.

So, fire up your printer, grab some river-grade filament, and start bringing your ideas to life. The river is waiting, and your perfectly customized gear is ready to hit the rapids. Now go forth, fellow river enthusiasts, design, print, and paddle with the confidence that you've not only improved your gear but also mastered a truly innovative skill. Happy printing, and happy paddling!