Have you ever stared at a pile of packages, each one a mystery, wondering where it’s headed or what precious cargo it holds? Or perhaps you’ve experienced that sinking feeling when a crucial item goes missing in transit, leaving you scrambling for answers? Trust me, I’ve been there. I remember one particularly frantic afternoon when a critical shipment of prototypes for a client vanished into the logistical ether. We had basic shipping labels, but no robust way to internally track *which specific item* was in *which box*, or *when* it was supposed to arrive at each internal checkpoint. The chaos that ensued trying to reconcile inventory, re-create lost items, and appease an anxious client taught me a harsh but invaluable lesson: generic labels just don't cut it. What we desperately needed was a more granular, reliable system – a way to give each parcel its own unique identity, its own story, its own internal beacon. And that, my friends, is where the often-overlooked, yet incredibly powerful, printable parcel asset tag steps onto the stage.

This isn't just about sticking a label on a box; it's about embedding intelligence, ensuring accountability, and streamlining your entire workflow. Whether you're a small e-commerce entrepreneur juggling dozens of daily orders, a logistics manager overseeing complex supply chains, or even just someone who frequently ships valuable items, understanding and implementing effective parcel asset tagging can revolutionize how you manage your inventory, track shipments, and ultimately, safeguard your peace of mind. Forget the days of guesswork and frantic searches. This comprehensive guide is designed to equip you with everything you need to know about printable parcel asset tags – from the foundational "why" to the intricate "how-to," advanced strategies, and common pitfalls to avoid. We'll delve deep into how these unassuming tags can transform your operations, boost efficiency, and save you from those dreaded "where is it?" moments. Get ready to embark on a journey that will demystify asset tracking and empower you to take control of your parcels like never before.

Table of Contents

- [The Unsung Hero: Demystifying the Printable Parcel Asset Tag](#the-unsung-hero-demystifying-the-printable-parcel-asset-tag)

- [Beyond the Label: Why Your Parcels Deserve Top-Tier Tracking](#beyond-the-label-why-your-parcels-deserve-top-tier-tracking)

- [Your Blueprint for Success: Crafting the Perfect Printable Parcel Asset Tag](#your-blueprint-for-success-crafting-the-perfect-printable-parcel-asset-tag)

- [The Tech Toolkit: Software & Hardware for Flawless Tag Production](#the-tech-toolkit-software--hardware-for-flawless-tag-production)

- [Design That Delivers: Best Practices for Effective Parcel Asset Tags](#design-that-delivers-best-practices-for-effective-parcel-asset-tags)

- [Mastering the Workflow: Integrating Tags into Your Shipping & Inventory](#mastering-the-workflow-integrating-tags-into-your-shipping--inventory)

- [Advanced Horizons: Elevating Your Asset Tracking Game](#advanced-horizons-elevating-your-asset-tracking-game)

- [Dodging Disasters: Common Pitfalls and How to Avoid Them](#dodging-disasters-common-pitfalls-and-how-to-avoid-them)

- [The Future is Tagged: Innovations in Parcel Asset Management](#the-future-is-tagged-innovations-in-parcel-asset-management)

- [The ROI of Organization: Making the Business Case for Asset Tags](#the-roi-of-organization-making-the-business-case-for-asset-tags)

- [How to Choose the Best Printable Parcel Asset Tag Solution for Your Needs](#how-to-choose-the-best-printable-parcel-asset-tag-solution-for-your-needs)

- [Common Pitfalls to Avoid When Implementing Parcel Asset Tags](#common-pitfalls-to-avoid-when-implementing-parcel-asset-tags)

- [Advanced Tips for Experts: Optimizing Your Parcel Asset Tag System](#advanced-tips-for-experts-optimizing-your-parcel-asset-tag-system)

- [Conclusion](#conclusion)

---

The Unsung Hero: Demystifying the Printable Parcel Asset Tag

Let's start at the very beginning. What exactly *is* a printable parcel asset tag? At its core, it's a unique identifier, printed onto an adhesive label, applied directly to a parcel or package. But it's so much more than just a sticker. Think of it as a digital fingerprint for your physical goods, allowing you to track, monitor, and manage individual items or entire shipments with unprecedented precision. Unlike a generic shipping label that primarily focuses on destination and carrier information, an asset tag delves deeper into the *contents*, *value*, *origin*, *internal tracking numbers*, and *specific handling instructions* relevant to *your* internal operations.

Here’s a breakdown of what makes these tags so special and why they're gaining traction:

1. Unique Identification: Each tag carries a distinct code (barcode, QR code, alphanumeric string) that links directly to a database entry containing detailed information about the parcel and its contents. This is the cornerstone of effective tracking.

2. Internal Tracking: While carriers provide external tracking, asset tags offer *internal* visibility. You know exactly where a parcel is within *your* facility, during packing, staging, and even after it leaves your dock but before the carrier scan.

3. Content Specificity: Tags can detail what's *inside* the parcel, not just the destination. This is invaluable for high-value items, serialized products, or shipments with multiple components.

4. Customizable Information: Unlike rigid carrier labels, you dictate what data goes on your asset tag: batch numbers, project codes, internal SKU, department, order ID, special handling notes, etc.

5. Enhanced Security & Accountability: By tracking specific parcels internally, you reduce the risk of loss, theft, or misplacement. If something goes missing, you can pinpoint its last known location within your system.

6. Improved Inventory Management: Asset tags can seamlessly integrate with your inventory management system, providing real-time updates on what's been packed, shipped, and is en route.

7. Quality Control Integration: You can link tags to quality checks performed before packaging, ensuring only approved items are shipped.

8. Cost-Effectiveness: Printable tags, especially when generated in-house, are often a more economical solution for detailed internal tracking compared to custom pre-printed labels from third parties.

9. Scalability: From a handful of parcels a day to thousands, the system can scale with your needs, accommodating growth without requiring an overhaul.

10. Ease of Implementation: With modern software and printers, generating and applying these tags is surprisingly straightforward, even for beginners.

11. Durability Options: You can choose various label materials (thermal, synthetic, waterproof) to match the environment and handling conditions your parcels will endure.

12. Regulatory Compliance (for certain industries): In some sectors, detailed tracking of specific assets or components within a shipment is a regulatory requirement, and asset tags facilitate this compliance. For instance, in pharmaceuticals, tracking specific batches of medicine down to the individual shipping unit is paramount.

Imagine a scenario where you're shipping delicate lab equipment. A standard label tells you it's going from A to B. A printable parcel asset tag can tell you: "This is parcel #LA-2023-001, containing spectrophotometer Model X, serial #12345, calibration due date 12/31/2024, packed by John Doe on 10/26/2023, requires 'Fragile' handling, and is part of Project Alpha." That's the power of specificity and internal control!

---

Beyond the Label: Why Your Parcels Deserve Top-Tier Tracking

Why go the extra mile with a printable parcel asset tag when standard shipping labels exist? The answer lies in the layers of control, efficiency, and peace of mind these tags provide, extending far beyond what a basic tracking number can offer. It’s about more than just knowing *if* a package arrived; it’s about knowing *what* was in it, *who* handled it, and *when* at every internal touchpoint.

Here are compelling reasons why investing in robust asset tagging for your parcels is a game-changer:

1. Minimizing Loss and Damage: Detailed internal tracking helps identify where a parcel was last scanned if it goes missing or is damaged. This reduces shrinkage and streamlines claims.

2. Boosting Operational Efficiency: Automating identification and data capture reduces manual errors, speeds up packing and sorting processes, and frees up staff for more complex tasks.

3. Enhancing Customer Satisfaction: Faster, more accurate shipping means fewer delays, fewer lost items, and happier customers. You can answer "where is my stuff?" with confidence.

4. Streamlining Inventory Management: Asset tags seamlessly integrate with inventory systems, providing real-time data on what's being shipped, what's in transit, and what needs replenishment. This was a lifesaver for my team when we scaled up our e-commerce operation; knowing exactly which product was in which outgoing box before the carrier picked it up meant our inventory counts were always spot-on.

5. Improving Auditing and Compliance: For businesses dealing with regulated goods or requiring strict chain-of-custody, asset tags provide an immutable audit trail for each parcel.

6. Facilitating Returns and Exchanges: When a parcel comes back, its asset tag immediately links it to the original order and contents, simplifying the return process.

7. Reducing Human Error: Manual data entry is prone to mistakes. Scannable asset tags eliminate this, ensuring accuracy from packing to dispatch.

8. Optimizing Warehouse Logistics: Tags enable more efficient sorting, staging, and loading of parcels, optimizing space and reducing bottlenecks in busy warehouses.

9. Gaining Data Insights: The data collected from asset tags can reveal patterns in shipping times, common points of delay, or areas needing improvement in your logistics chain.

10. Protecting High-Value Shipments: For expensive or critical items, the added layer of tracking and accountability provided by an asset tag is indispensable, offering an extra layer of security beyond standard carrier tracking.

11. Scalability and Adaptability: A well-implemented asset tagging system can grow with your business, adapting to increased volumes or changes in product lines without major overhauls.

12. Competitive Advantage: Businesses that offer superior tracking and fewer shipping errors stand out. It builds trust and enhances your reputation in a crowded market. I've found that customers appreciate transparency, and while they don't see our internal asset tags, the smooth, error-free delivery they experience is a direct result of our meticulous internal tracking.

Think of the difference between knowing "a package was sent" and knowing "Package #XYZA-789, containing customer order #4567, SKU #PRODUCT-ABC, was packed by Jane at 10:15 AM, scanned onto pallet 3 at 10:30 AM, and loaded onto carrier truck #123 at 11:00 AM." That’s the power of granular detail and why your parcels deserve this level of dedicated attention.

---

Your Blueprint for Success: Crafting the Perfect Printable Parcel Asset Tag

Ready to dive into the practicalities? Creating an effective printable parcel asset tag involves more than just hitting 'print'. It's about thoughtful design, strategic data inclusion, and choosing the right materials to ensure longevity and readability. This section will guide you through the essential steps and considerations.

Here’s your blueprint for success:

1. Define Your Data Needs: Before designing, determine *what information* you absolutely need on the tag. This could include order ID, SKU, batch number, destination internal code, packing date, handler ID, special instructions (e.g., "Fragile," "Keep Upright"). Don't overcrowd it, but include essentials.

2. Choose Your Identification Method:

- Barcodes (1D): Common (Code 39, Code 128, EAN), good for sequential numbers, widely supported by scanners.

- QR Codes (2D): Can store more data (URLs, rich text), scannable by smartphones, more robust against damage. I personally prefer QR codes for internal tracking because they offer more flexibility if I need to link to an internal database entry or a specific packing checklist directly from a phone.

- RFID (Advanced): Not strictly "printable" in the same way, but sometimes integrated with printable labels. Offers passive scanning without line of sight, but requires specialized equipment and higher cost.

3. Select the Right Label Material:

- Thermal Paper: Cost-effective, common for shipping labels, but can fade with heat/light and is not waterproof.

- Direct Thermal Synthetic: More durable than paper, water-resistant, good for many applications.

- Thermal Transfer Synthetic: Most durable, chemical-resistant, waterproof, suitable for harsh environments and long-term tracking. Requires a ribbon.

- Adhesive Strength: Consider permanent vs. removable adhesive. For parcels, permanent is usually preferred to prevent accidental detachment.

4. Design for Readability and Scanability:

- High Contrast: Ensure dark text/barcode on a light background.

- Adequate Size: Make sure the barcode/QR code is large enough to be easily scanned, even from a slight distance.

- Clear Layout: Organize information logically. Use bolding for critical data.

- Minimalist Approach: Avoid clutter. Every element should serve a purpose.

5. Choose Your Printing Method:

- Thermal Printers: Ideal for high-volume, fast, and cost-effective label printing. Direct thermal or thermal transfer options.

- Inkjet/Laser Printers: Suitable for lower volumes or when color coding is desired, but labels may be less durable than thermal.

6. Integrate with Your Systems:

- Connect your label printing software to your inventory management system (IMS), order management system (OMS), or enterprise resource planning (ERP) system. This automates data population and reduces manual input errors. My personal anecdote: When we finally integrated our label software with our Shopify order system, it felt like magic. No more copy-pasting order numbers, just a click and the printable parcel asset tag was ready with all the necessary info.

7. Test Thoroughly: Print a batch of tags and test them with your scanners and under various conditions. Check for adhesion, readability, and data accuracy. Don't skip this step!

8. Develop a Standard Operating Procedure (SOP): Clearly document how and when tags are printed, applied, and scanned. Train your team diligently.

9. Consider Security Features: For high-value items, think about tamper-evident labels or incorporating security holograms (though this adds complexity and cost).

10. Future-Proofing: Choose a system that can adapt to future needs, such as adding more data fields or integrating with new tracking technologies.

11. Batch Printing vs. On-Demand: Decide if you'll print tags in batches for common items or generate them on-demand for each unique parcel. On-demand offers greater flexibility.

12. Backup and Data Redundancy: Ensure your asset tag data is regularly backed up to prevent loss.

By following this blueprint, you'll create a robust and reliable asset tagging system that serves your operational needs effectively.

---

The Tech Toolkit: Software & Hardware for Flawless Tag Production

You've got the blueprint, now let's talk tools! To truly master the printable parcel asset tag, you need the right combination of software and hardware. This isn't about buying the most expensive gear, but selecting solutions that fit your volume, budget, and specific operational demands.

Here’s your essential tech toolkit:

1. Label Design and Printing Software:

- Dedicated Label Software (e.g., BarTender, ZebraDesigner, NiceLabel): These are industry powerhouses, offering extensive design flexibility, database integration, and automation features. Ideal for complex needs and high volumes.

- General Design Software (e.g., Adobe Illustrator, Canva): Can be used for simple, static designs, but lack database integration for dynamic data. Not recommended for high-volume asset tagging.

- Built-in Features of IMS/OMS/ERP: Many modern inventory or order management systems (like Shopify, ShipStation, or even some ERPs) have integrated label printing capabilities that can generate basic asset tags. This is often the easiest starting point.

- Spreadsheet-Based Solutions: For very small operations, you might generate sequential numbers in Excel/Google Sheets and use a mail-merge function with a word processor to print labels. This is highly manual but can work in a pinch.

2. Label Printers:

- Desktop Thermal Printers (e.g., Zebra ZD421, Dymo LabelWriter, Brother QL series): Compact, fast, and relatively inexpensive. Perfect for small to medium businesses printing hundreds of labels a day. My go-to for my small e-commerce venture is a thermal printer; it's a game-changer because it means no more ink cartridges, just rolls of labels, and it's incredibly fast.

- Industrial Thermal Printers (e.g., Zebra ZT411, Sato CL4NX): Heavy-duty, designed for 24/7 operation and high-volume printing (thousands of labels daily). Essential for large warehouses and logistics hubs.

- Inkjet/Laser Printers (with label sheets): Suitable for very low volumes or when color is crucial. Slower, higher cost per label, and labels are generally less durable than thermal.

3. Barcode/QR Code Scanners:

- Handheld Scanners (Corded/Cordless): The workhorses of asset tracking. Cordless options offer greater mobility in a warehouse setting.

- Fixed-Mount Scanners: Integrated into conveyor belts or workstations for high-speed, automated scanning.

- Smartphone Apps: Many free or paid apps can scan barcodes/QR codes, turning a smartphone into a basic scanner. Excellent for quick checks or very low-volume operations. However, for dedicated use, a proper scanner is far more efficient and reliable.

4. Label Stock (Consumables):

- Rolls of Thermal Labels: Direct thermal or thermal transfer, in various sizes and materials (paper, synthetic). Ensure compatibility with your printer.

- Adhesive Strength: Consider different adhesive types based on how long the tag needs to stay on the parcel and the surface material.

- Specialty Labels: For extreme conditions, you might need waterproof, chemical-resistant, or freezer-grade labels.

5. Data Management System:

- Inventory Management System (IMS): Crucial for linking asset tag data to your product inventory, stock levels, and movements.

- Order Management System (OMS): Integrates order details with asset tag generation, ensuring accuracy and efficiency from order placement to shipment.

- Spreadsheet (for beginners): While basic, a well-structured spreadsheet can serve as a rudimentary database for tracking asset tag assignments for very small operations.

- Cloud-Based Asset Tracking Software: Many dedicated solutions exist that manage asset data, generate tags, and provide tracking dashboards.

6. Backup Power Supply (UPS): For critical printing stations, a UPS ensures uninterrupted operation during power fluctuations or outages.

7. Network Connectivity: Reliable Wi-Fi or Ethernet is essential for software updates, database access, and cloud-based solutions.

8. Workstation: A dedicated, organized space for printing and applying tags helps maintain efficiency.

Choosing the right combination of these tools will empower you to create, manage, and track your printable parcel asset tags with confidence and precision. Remember, the best tool is the one that fits *your* specific needs and budget, not necessarily the most advanced one on the market.

---

Design That Delivers: Best Practices for Effective Parcel Asset Tags

A printable parcel asset tag is only as good as its design. A poorly designed tag can lead to scanning errors, misinterpretations, and ultimately, undermine your entire tracking system. Good design isn't just about aesthetics; it's about functionality, efficiency, and clarity.

Here are the best practices for designing asset tags that truly deliver:

1. Prioritize Scanability:

- High Contrast: Always ensure a dark barcode/QR code on a light, non-reflective background.

- Quiet Zones: Leave clear space (a "quiet zone") around the barcode/QR code. This blank margin is critical for scanners to properly "read" the code.

- Optimal Size: Don't make codes too small. Test different sizes with your scanner to find the sweet spot for quick, reliable reads.

- Orientation: Print barcodes horizontally when possible, as most handheld scanners are designed for this orientation.

2. Keep It Clean and Uncluttered:

- Essential Information Only: Resist the urge to cram too much data onto the tag. Only include what's absolutely necessary for identification and internal tracking.

- Logical Hierarchy: Arrange information clearly. Use larger fonts or bolding for the most critical data (e.g., the unique ID number).

- White Space is Your Friend: Ample white space improves readability and reduces visual noise.

3. Choose the Right Font:

- Legible Typefaces: Use clear, sans-serif fonts (e.g., Arial, Helvetica, Roboto) that are easy to read, even at small sizes.

- Appropriate Font Size: Ensure printed text is large enough to be easily read by the human eye without strain.

4. Incorporate Human-Readable Data:

- Even with a scannable code, always include a human-readable version of the unique identifier (e.g., the alphanumeric code below a barcode). This is crucial for manual entry or troubleshooting if a scan fails.

- Add key descriptive text like "Order #," "SKU," or "Batch #" next to the respective data point.

5. Consider Durability Elements:

- Material Selection: As discussed, choose labels that can withstand the expected environmental conditions (moisture, temperature, abrasion).

- Protective Coatings: For labels in harsh environments, consider laminate coatings to protect against smudging, scratches, and moisture.

- Adhesive: Select an adhesive strong enough to remain affixed for the entire journey of the parcel.

6. Standardize Your Layout:

- Create a consistent template for all your printable parcel asset tags. This makes them instantly recognizable, reduces confusion, and speeds up processing for your team.

- Use consistent placement for barcodes, logos, and critical data fields.

7. Incorporate Branding (Optional):

- A small company logo can be included, but ensure it doesn't interfere with scanability or readability of critical data.

8. Color Coding (if applicable):

- For internal sorting or specific handling instructions, color-coded tags can be incredibly useful (e.g., red for urgent, blue for international). However, ensure the color doesn't compromise barcode contrast.

9. Clear Call to Action/Instructions (if needed):

- For specific handling, a small icon or text (e.g., "Fragile," "This Side Up") can be incorporated, but use sparingly.

10. Test, Test, Test:

- Print samples on your chosen material and printer. Scan them with all your intended scanners.

- Test under different lighting conditions.

- Try smudging, slightly tearing, or bending a test tag to see how robust it is. My personal experience: I once designed a beautiful tag, only to realize the barcode was too close to the edge and kept getting cut off by the printer. A quick design tweak based on testing saved us a lot of headaches!

11. Scalability in Mind:

- Design a template that can accommodate varying data lengths if necessary, without breaking the layout.

12. Version Control:

- If you iterate on your tag designs, keep track of different versions to ensure consistency across your operations.

By adhering to these best practices, your printable parcel asset tags will not only look professional but, more importantly, function flawlessly, becoming a reliable cornerstone of your tracking and logistics.

---

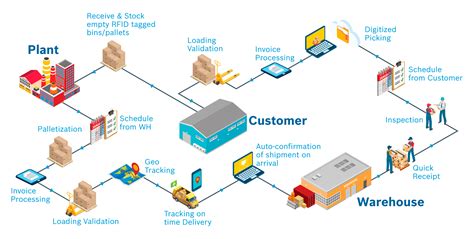

Mastering the Workflow: Integrating Tags into Your Shipping & Inventory

Designing and printing the perfect printable parcel asset tag is only half the battle. The real magic happens when you seamlessly integrate these tags into your daily shipping and inventory workflows. This transformation moves asset tagging from a mere label to a powerful operational tool.

Here’s how to master the workflow integration:

1. Pre-Assembly/Pre-Packing Tagging:

- Assign Early: For complex items or kits, assign and tag individual components *before* they are assembled or packed into the final parcel. This allows for granular tracking from the very beginning.

- Staging Area: Implement a tagging station in your staging area where products are gathered for an order, ensuring each item slated for a parcel gets its unique tag.

2. Order Picking Integration:

- When an order is picked, scan the product's internal SKU *and* the unique printable parcel asset tag that will be applied to its parcel. This links the physical product to its eventual shipping container in your system.

- Use mobile scanners for real-time updates as items are picked and moved towards packing.

3. Packing Station Efficiency:

- Dedicated Tagging Spot: Have a designated area at each packing station for printing and applying tags.

- Scan-to-Pack: As items are placed into a parcel, scan the item SKU and the parcel's asset tag. This confirms contents and updates your inventory system simultaneously. This is my absolute favorite part of the process – watching the inventory count update in real-time as a package is prepared for shipment is incredibly satisfying and eliminates so much manual reconciliation.

- Visual Confirmation: Train packers to visually confirm the correct tag is applied to the corresponding parcel based on order details.

4. Quality Control Checkpoints:

- Post-Packing Scan: After a parcel is sealed, perform a final scan of the printable parcel asset tag. This can trigger a "packed and ready" status in your system.

- Weight Verification: Link the asset tag scan to a weight scale to verify the parcel's weight matches expected contents, catching potential errors or missing items.

5. Staging and Loading Procedures:

- Pallet/Cage Tagging: For larger shipments, apply a master asset tag to pallets or cages, which links to all individual parcel asset tags contained within.

- Load Verification: Before a carrier truck departs, scan each parcel asset tag as it's loaded. This confirms all expected parcels are onboard and updates their status to "shipped" in your system, providing an accurate departure record.

6. Real-time Tracking and Reporting:

- Dashboard Visibility: Utilize your IMS/OMS dashboard to view the real-time status of all tagged parcels: "picked," "packed," "staged," "loaded," "shipped."

- Automated Alerts: Set up alerts for any anomalies, such as a parcel not being scanned at a particular checkpoint within a specified timeframe.

7. Returns Management:

- When a parcel is returned, scan its asset tag. This immediately pulls up its original order details, simplifying the return, refund, or exchange process and ensuring the returned item is correctly routed back into inventory or quality control.

8. Employee Training and Accountability:

- Clear SOPs: Provide detailed Standard Operating Procedures for every step involving asset tags.

- Regular Training: Conduct regular training sessions to ensure all staff are proficient in using the tagging system.

- User IDs: Assign unique user IDs to employees for scanning, so you can track who performed which action on a parcel.

9. Integration with Carrier Systems (if possible):

- While carrier labels are separate, some advanced systems can link your internal asset tag ID to the carrier's tracking number, providing a holistic view.

10. Problem Resolution:

- When a customer inquires about a missing item, the asset tag data provides precise internal tracking, helping you quickly identify where the item was last seen and initiate a more targeted search. My subjective opinion here: a robust asset tagging system drastically cuts down on the time spent investigating lost packages, transforming a stressful hunt into a data-driven inquiry.

11. Continuous Improvement:

- Regularly review your asset tag workflow. Are there bottlenecks? Areas for further automation? Use data from your tracking system to identify and implement improvements.

12. Physical Label Placement:

- Ensure the tag is placed on a flat, clean surface of the parcel, avoiding seams, corners, or areas prone to damage during handling.

By meticulously integrating printable parcel asset tags into every stage of your shipping and inventory process, you create a robust, transparent, and highly efficient system that empowers you with unparalleled control and visibility.

---

Advanced Horizons: Elevating Your Asset Tracking Game

Once you've mastered the basics of the printable parcel asset tag, it's time to look at how experts push the boundaries. This section is for those who want to move beyond foundational tracking and leverage asset tags for deeper insights, greater automation, and enhanced security.

Here’s how to elevate your asset tracking game:

1. Serialization and Batch Tracking:

- Individual Item IDs: For high-value or regulated goods, assign a unique serial number to *each individual item* within a parcel, and link these to the parcel's master asset tag. This provides end-to-end traceability down to the unit level.

- Batch-Specific Tags: Use asset tags that clearly indicate batch numbers for products, critical for recall management or quality control in manufacturing.

2. Dynamic Data Integration:

- Real-time Updates: Integrate your asset tag system with live data sources (e.g., IoT sensors, production line data) to print tags with dynamic information like "Last QC Check: Pass," "Temperature Range: 20-22C," or "Next Service Due: 30 Days."

- Conditional Printing: Set up rules where certain information or even different tag designs are printed based on specific order parameters (e.g., "Fragile" tag for delicate items, or a different color for international shipments).

3. Two-Factor Verification:

- Dual Tagging: Apply two different asset tags to a parcel – one internal, one for the recipient (or a specific department). This can be used for double-checking or for internal auditing purposes upon receipt.

- Digital Signatures: Incorporate a small QR code that, when scanned, requires a digital signature or password for confirmation, adding a layer of security for sensitive shipments.

4. Automated Scanning and Sorting: