We live in a world where personal responsibility and safety go hand-in-hand, especially when it comes to firearms. For many gun owners, the commitment to safety is paramount, and ensuring firearms are stored securely is non-negotiable. Traditional gun locks are effective, but as a long-time enthusiast of both firearms and 3D printing, I’ve often wondered about custom, accessible solutions. I remember one evening, rushing home from a range session, I realized I’d left a firearm unsecured for a brief moment. That quick flash of anxiety solidified for me: *every* gun needs to be locked, *every* time. It’s not just about compliance; it’s about peace of mind.

This deep dive into "3d printable gun locks" isn't just about the technology; it's about empowering you to enhance safety in a way that’s innovative and tailored. Whether you're a seasoned gun owner, a curious 3D printing hobbyist, or a parent looking for additional layers of protection, understanding the possibilities and limitations of these custom solutions is crucial. Let's explore how 3D printing can play a role in responsible firearm ownership, offering a new dimension to security.

The Why: Understanding the Need for 3D Printed Gun Locks

At its core, a gun lock is a safety device. It prevents unauthorized access, particularly from curious children or individuals who might misuse a firearm. While commercial locks are readily available, the appeal of a 3D printable gun lock often lies in its potential for customization, affordability, and the sheer satisfaction of a DIY solution.

Here are scenarios where a 3D printed gun lock can be particularly relevant:

- Preventing Accidental Discharge: A lock renders the firearm inoperable, drastically reducing the risk of a tragic accident. I once saw a video of a child finding an unlocked gun, and it was a chilling reminder of why every second counts.

- Deterring Unauthorized Access: For homes with children or guests, a lock provides an essential barrier. It's not about hiding the gun, but about securing it so only you can access it when needed.

- Temporary Security Solution: Perhaps you're waiting for a permanent safe, or need a quick way to secure a new acquisition. A 3D printed lock can fill this gap effectively.

- Custom Fit for Unique Firearms: Some firearms have unusual trigger guard shapes or designs that standard locks don't fit well. With 3D printing, you can design a lock that fits *perfectly*. I remember trying to find a lock for an older, less common revolver, and the options were so limited. Custom printing solves that.

- Educational Project: For 3D printing enthusiasts, designing and printing a functional gun lock can be an excellent learning experience, blending CAD skills with a real-world safety application.

- Cost-Effective Option: While not meant to replace high-security measures, a 3D printed lock can be a very economical way to add an extra layer of safety, especially for multiple firearms.

Design & Functionality: What Makes a Good 3D Printed Lock?

Designing a 3D printable gun lock goes beyond just making something that fits. It needs to be robust, reliable, and functional. Think about the common types of commercial locks and how you might adapt their principles.

Consider these design elements:

- Trigger Guard Lock: This is the most common and often easiest to implement. It encases the trigger guard, preventing any finger from reaching the trigger. A good design will snap securely into place or use a pin. I've found designs that use a simple two-piece clam shell often work well.

- Chamber Block: This type inserts into the firearm's chamber, preventing a round from being loaded. While more complex, it offers an additional layer of security by physically blocking the firing mechanism.

- Magazine Well Lock: For firearms with detachable magazines, a lock that secures the magazine well can prevent a magazine from being inserted, further disabling the weapon.

- Disassembly Pin Lock: Some advanced designs aim to replace a critical pin (e.g., a takedown pin) with a custom, locked component, making the firearm inoperable without the key.

- Integrated Locking Mechanism: Instead of external components, some designs aim for a more integrated approach, perhaps using a custom-designed sliding pin or bolt secured by a small padlock.

- Retention Features: Look for designs that securely hold the lock in place, preventing it from being easily pried off or bypassed. Good examples use a tight fit combined with a padlock hole.

- Visibility: A brightly colored lock can serve as a clear visual indicator that the firearm is secured, adding another layer of safety awareness.

Materials & Printing: Choosing the Right Stuff

The strength and reliability of your 3D printable gun lock heavily depend on the material and print settings. Trust me, you don’t want to mess this up by choosing flimsy material or inadequate infill.

Here’s what I learned the hard way about materials:

- PETG: My personal go-to. It offers a good balance of strength, impact resistance, and layer adhesion. It's more durable than PLA and less prone to warping than ABS, making it a fantastic choice for functional parts that need to withstand a bit of stress. I find this approach works best for small, strong parts.

- ABS: Known for its strength and heat resistance. If your firearm might be exposed to higher temperatures (e.g., in a hot car), ABS is a contender. However, it can be trickier to print due to warping, requiring an enclosure.

- Nylon: Offers incredible strength and flexibility, making it highly durable. It's more advanced to print, often requiring specific print surfaces and high temperatures, but results in a very robust lock.

- PLA: While easy to print, PLA is generally too brittle for a critical security device like a gun lock. It can shatter under impact or stress. Avoid it for primary security, unless it's strictly for fit-testing.

- High Infill Density: Regardless of material, always print your gun lock with a very high infill density, preferably 80-100%. This ensures maximum strength and rigidity.

- Strong Perimeters: Increase the number of perimeters (wall thickness) to 4 or more. This significantly enhances the part's strength.

- Optimized Layer Height: A finer layer height (e.g., 0.16mm - 0.2mm) can improve part strength by creating better layer adhesion, though it increases print time.

Legal & Ethical Considerations: Navigating the Landscape

This is arguably the most crucial section. A 3D printable gun lock, while a safety tool, operates in a sensitive area. Always be aware of your local, state, and federal laws regarding firearm accessories, security, and 3D printed components.

Key considerations include:

- Legal Compliance: In many jurisdictions, laws mandate specific types of gun locks or storage. Ensure your 3D printed solution complements, and does not replace, any legally required measures. Consult local authorities or legal counsel if unsure.

- Liability: If an accident occurs with a firearm secured by a homemade lock, you could face significant liability. This is why commercial, tested, and certified locks are often recommended for primary security.

- Intent and Use: A 3D printed gun lock is intended solely for safety and security. It should never be designed or used to facilitate illegal activity or to bypass existing laws.

- Ethical Responsibility: As a gun owner and 3D printing enthusiast, you have an ethical obligation to promote safe firearm handling and storage. Sharing designs for locks should always come with clear disclaimers about responsibility and legal compliance.

- Testing and Reliability: Unlike commercially available locks that undergo rigorous testing, your 3D printed lock will not. It's your responsibility to thoroughly test its strength and functionality, but never rely solely on it for critical security where certified locks are required. When I design anything related to safety, I always over-engineer it.

- Bypass Potential: Understand that no lock is impenetrable. A 3D printed lock, especially one made from plastic, may be less resistant to tampering or forced entry than steel locks. Its primary purpose is to deter and delay, not to withstand determined attempts.

Beyond the Basics: Advanced Customization & Security

Once you’ve mastered the fundamentals, the world of 3D printing offers incredible scope for innovation. For the veteran 3D printer or gun enthusiast, here are ways to push the envelope:

- Integrated Combination Locks: Explore designs that incorporate small, commercially available combination lock mechanisms directly into the 3D printed part, eliminating the need for an external padlock.

- Biometric Integration (Conceptual): While complex, some hobbyists explore concepts for embedding small fingerprint scanners (like those from old phones or cheap modules) to create truly unique, personalized access. This is still largely theoretical for practical gun locks but showcases the potential.

- Custom Aesthetics: Beyond pure function, you can customize the look of your lock. Match it to your firearm's finish, add textured grips, or even engrave personal identifiers (not to be confused with serial numbers!).

- Modularity: Design a lock system that uses interchangeable parts, allowing for quick adaptation to different firearm models or security needs without printing an entirely new lock.

- Material Blending: Experiment with multi-material printing (if your printer supports it) to combine materials with different properties, like a rigid core with a softer, non-marring exterior.

- Smart Lock Concepts: Integrate simple IoT (Internet of Things) sensors to detect if the lock is in place or has been tampered with, sending alerts to your phone. This is a highly advanced project but a fascinating frontier for those technically inclined.

Common Pitfalls: What to AVOID When Creating 3D Printed Gun Locks

As with any DIY project, especially one related to safety, there are pitfalls to avoid. Don’t be like me and learn these the hard way through frustration or, worse, compromise.

- Using Insufficient Material: As mentioned, PLA is generally a no-go for load-bearing or security components. Don't cheap out on filament for something this important.

- Low Infill & Perimeters: This is a recipe for a weak lock. Always max out your infill and perimeter count. You're printing a security device, not a vase!

- Ignoring Fitment Issues: A loose lock is a useless lock. Ensure your design has tight tolerances for a secure fit on your specific firearm. Test it rigorously before relying on it.

- Overlooking Thermal Expansion: Plastic expands and contracts with temperature changes. A lock that fits perfectly at room temperature might become too tight or too loose in extreme conditions. Design with slight clearances.

- Relying on Friction Alone: While a snug fit is good, a well-designed 3D printed gun lock should ideally incorporate a padlock or a secure pin mechanism. Friction alone is easily defeated.

- Bypassing Legal Requirements: Never use a 3D printed lock as an excuse to ignore state or federal laws regarding firearm storage or safety devices. It's a supplemental tool, not a loophole.

- Sharing Untested Designs Recklessly: If you plan to share your designs, ensure they are thoroughly tested and accompanied by clear disclaimers regarding materials, print settings, and the absolute necessity of personal responsibility and legal compliance.

Tips for Personalizing Your 3D Printed Gun Lock

Making your 3D printed gun lock unique can be satisfying. Beyond the practicalities, here’s how to add a personal touch and ensure maximum effectiveness.

- Measure Twice, Print Once: The most crucial personalization for a gun lock is a precise fit. Use calipers to measure your specific firearm's trigger guard, action, or other areas the lock will secure. This ensures it's truly custom and effective.

- Consider Color for Visibility: Print your lock in a bright, noticeable color (like neon green or orange) to make it instantly recognizable as a safety device. This is my favorite strategy because it saved me countless times from forgetting to re-lock a firearm immediately after cleaning.

- Ergonomic Design: While secure, a lock can still be user-friendly. Design subtle finger grooves or textured surfaces to make it easier to handle and install.

- Add Personal Markings (Non-Identifiable): Engrave a unique pattern, your initials (not for identification purposes, but just a personal touch), or a small, meaningful symbol on the lock's exterior. Keep it subtle and discreet.

- Iterate and Refine: Don't expect perfection on the first print. Print prototypes in cheaper PLA to test the fit, then refine your design before printing the final version in a stronger material. This process is crucial for effective results.

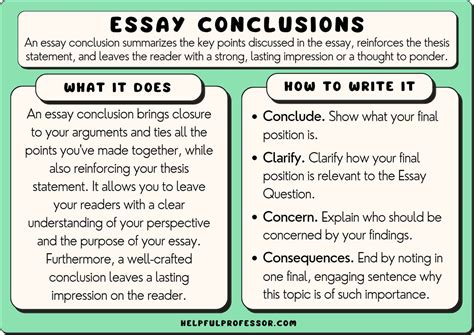

Conclusion

The journey into 3D printable gun locks is a fascinating intersection of technology, personal safety, and responsible gun ownership. While they offer incredible potential for customization and accessibility, it’s vital to approach them with the seriousness they deserve, always prioritizing safety, legal compliance, and reliable engineering. By understanding the materials, design principles, and ethical considerations, you can leverage 3D printing to contribute positively to your firearm security strategy. Now go forth, design responsibly, and keep those firearms secure! Your peace of mind, and the safety of those around you, are worth every bit of effort.