Have you ever dreamt of wearing your own art, seeing your unique designs flow elegantly across a luxurious textile, or gifting a truly personalized, high-end item? For years, the idea of translating digital dreams onto tangible fabric felt like a distant, complex craft reserved for industrial giants. I remember vividly my early days of trying to customize textiles – a frustrating dance with iron-on transfers that peeled, or clumsy attempts at screen printing that left me with more dye on my hands than on the fabric. The dream of a smooth, vibrant, and *truly personal* textile seemed out of reach.

But then, I discovered the enchanting world of printable silk fabric, and my entire creative landscape shifted. It was like finding a secret garden where technology met tradition, allowing for unparalleled customization and breathtaking results. This isn't just about putting a picture on cloth; it's about infusing your very essence, your artistic vision, onto a material that embodies elegance, comfort, and timeless beauty.

This comprehensive guide is born from countless hours of experimentation, research, and a deep-seated passion for textile innovation. Whether you're a budding DIY enthusiast, a seasoned fashion designer, a small business owner looking to differentiate, or simply curious about bringing your digital art to life, you’re in the right place. We're going to dive deep into everything you need to know about printable silk fabric – from its luxurious appeal and various printing methods to expert tips, common pitfalls, and how to transform your vision into a tangible masterpiece. Trust me, you don’t want to miss this journey into the silky smooth future of customization!

---

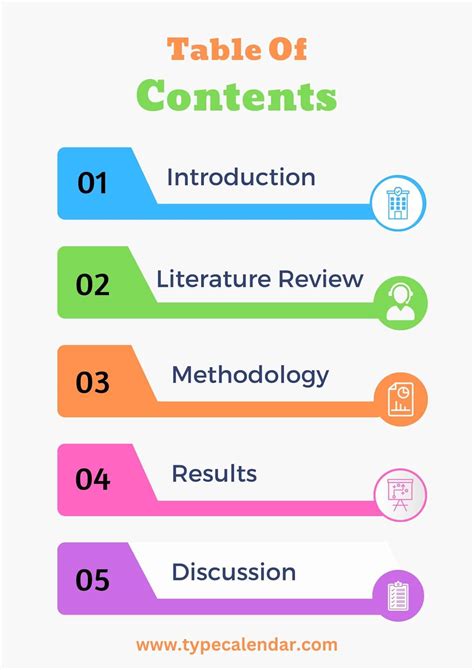

Table of Contents

- [The Allure of Silk: Why Print on This Luxurious Canvas?](#the-allure-of-silk-why-print-on-this-luxurious-canvas)

- [Demystifying Printable Silk: What Exactly Is It?](#demystifying-printable-silk-what-exactly-is-it)

- [The Art of Impression: A Deep Dive into Silk Printing Methods](#the-art-of-impression-a-deep-dive-into-silk-printing-methods)

- [From Concept to Creation: Designing for Your Printable Silk Project](#from-concept-to-creation-designing-for-your-printable-silk-project)

- [Unleashing Creativity: Inspiring Projects & Applications for Printable Silk](#unleashing-creativity-inspiring-projects--applications-for-printable-silk)

- [Navigating the Nuances: Choosing & Sourcing Your Printable Silk Fabric](#navigating-the-nuances-choosing--sourcing-your-printable-silk-fabric)

- [The Care & Keeping of Your Printed Silk Treasures](#the-care--keeping-of-your-printed-silk-treasures)

- [Troubleshooting Your Silk Printing Journey: Common Challenges & Solutions](#troubleshooting-your-silk-printing-journey-common-challenges--solutions)

- [Beyond the Hobby: Turning Printable Silk into a Thriving Business](#beyond-the-hobby-turning-printable-silk-into-a-thriving-business)

- [How to Choose the Best Printable Silk Fabric for Your Needs](#how-to-choose-the-best-printable-silk-fabric-for-your-needs)

- [Common Pitfalls to Avoid in Your Printable Silk Fabric Journey](#common-pitfalls-to-avoid-in-your-printable-silk-fabric-journey)

- [Advanced Tips for Experts: Elevating Your Printable Silk Fabric Game](#advanced-tips-for-experts-elevating-your-printable-silk-fabric-game)

- [Conclusion: Your Silk Canvas Awaits!](#conclusion-your-silk-canvas-awaits)

---

The Allure of Silk: Why Print on This Luxurious Canvas?

Before we even touch on the "printable" aspect, let's talk about silk itself. Why is this natural fiber so revered, and what makes it the ultimate choice for transforming your designs into wearable art or exquisite décor? It’s not just a fancy name; silk brings a host of unparalleled qualities to the table.

1. Unmatched Luster and Drape: Silk possesses a natural sheen that catches the light beautifully, giving printed designs an almost ethereal glow. Its fluid drape allows garments and accessories to flow gracefully, enhancing the visual appeal of any pattern. I once printed a flowing botanical pattern on silk charmeuse, and the way it shimmered and moved was simply captivating – a visual feast!

2. Luxurious Feel Against the Skin: There’s nothing quite like the smooth, soft, and cool touch of silk. It’s hypoallergenic, breathable, and incredibly comfortable, making it ideal for everything from high-fashion apparel to delicate sleep masks.

3. Exceptional Color Vibrancy: This is where silk truly shines for printing. Its protein structure readily accepts dyes, resulting in incredibly rich, saturated, and true-to-life colors. Designs pop with a depth and clarity that are hard to achieve on other fabrics.

4. Strength and Durability: Despite its delicate appearance, silk is one of the strongest natural fibers. When cared for properly, printed silk items can last for years, retaining their color and integrity.

5. Breathability and Temperature Regulation: Silk is a natural thermoregulator, keeping you cool in summer and warm in winter. This makes printed silk scarves, blouses, and linings practical as well as beautiful.

6. Hypoallergenic Properties: For those with sensitive skin or allergies, silk is a godsend. It's naturally resistant to dust mites, mold, and fungi, making it a healthy choice for apparel and bedding.

7. Lightweight Elegance: Silk fabric is incredibly light, allowing for voluminous designs without adding bulk, perfect for flowing dresses, scarves, and intricate drapes.

8. Versatility in Texture: From the smooth gloss of charmeuse to the subtle texture of dupioni or the sheer transparency of chiffon, silk offers a range of textures that can enhance different design aesthetics.

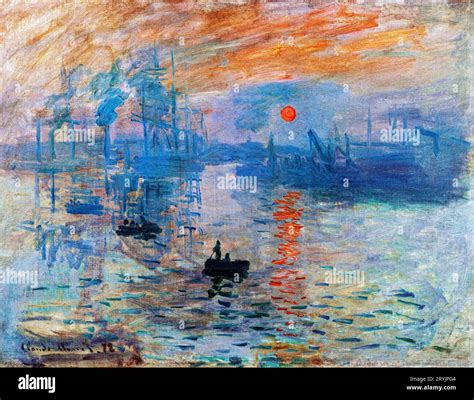

9. A Canvas for Art: Artists and designers often choose silk because it elevates their work. A painting on canvas is one thing, but a unique print on a flowing silk scarf becomes a wearable piece of art.

10. Eco-Friendly Potential: As a natural fiber, silk is biodegradable. When sourced responsibly and printed with eco-conscious dyes, it can be a more sustainable choice than many synthetic fabrics.

11. Perceived Value: Items made from silk inherently carry a higher perceived value, both commercially and personally. Gifting a custom-printed silk item feels truly special.

12. The "Wow" Factor: Let's be honest, there's just something inherently impressive about custom printable silk fabric. When I first showed off a scarf I’d designed and printed myself, the immediate reaction was always, "Wow, that's silk? And *you* made the design?" It's a conversation starter!

Demystifying Printable Silk: What Exactly Is It?

So, we know why silk is amazing. But what makes it "printable"? This isn't just any old silk you grab from the fabric store. While you *can* attempt to print on untreated silk (and we'll touch on that), "printable silk fabric" typically refers to silk that has been specially prepared or treated to optimize it for various printing processes, especially digital printing.

1. The Core Concept: At its heart, printable silk fabric is silk that has been pre-treated with a special coating or solution that allows textile inks (especially those used in inkjet or digital printers) to adhere properly, prevent bleeding, and achieve vibrant, long-lasting colors.

2. Pre-treated for Digital Printing: The most common form of printable silk fabric you'll encounter is designed for digital textile printing. This pre-treatment is crucial for the ink to sit on the fabric surface before being thermally fixed, ensuring crisp lines and bright hues.

3. Types of Silk Used: Almost any weave of silk can be made printable. Common choices include:

- Silk Habotai: Lightweight, soft, and slightly sheer, ideal for scarves and linings.

- Silk Charmeuse: Luxurious, glossy front with a dull matte back, perfect for high-end apparel.

- Silk Crepe de Chine: A slightly textured, matte finish with excellent drape, great for blouses and dresses.

- Silk Twill: Known for its diagonal rib pattern, very durable and opaque, often used for scarves and ties.

- Silk Chiffon: Sheer, lightweight, and ethereal, fantastic for overlays and delicate designs.

4. Untreated vs. Pre-treated: Trying to print on untreated silk with inkjet textile inks is like trying to write on wax paper with a marker – the ink will spread, bleed, and likely not adhere permanently. Pre-treatment creates a receptive surface.

5. The Role of Gums and Acids: The pre-treatment often involves substances like starches, gums, or mild acids that modify the silk fibers' surface tension and pH, preparing them to absorb and bond with the specific dyes used in the printing process.

6. "Print-Ready" Fabric: When you buy printable silk fabric from a specialized supplier, it usually comes "print-ready," meaning all the preparation steps have been professionally done, and it's ready to go straight into your printer (or sent to a printing service).

7. DIY Pre-treatment: For the truly adventurous, it's possible to pre-treat silk at home, but it's a finicky process requiring specific chemicals and careful application. Most hobbyists opt for commercially pre-treated fabric.

8. Reactive Dyes vs. Pigment Inks: The type of pre-treatment often depends on the ink system. Reactive dyes (common for silk) require a specific pre-treatment to bond chemically with the fibers. Pigment inks, which sit more on the surface, might use a different binder-based pre-treatment.

9. Sublimation Printing: While often associated with synthetics, special coatings can make silk receptive to sublimation dyes, offering another pathway for vivid, durable prints.

10. Understanding GSM (Grams Per Square Meter): The weight of the silk matters. Heavier silks (higher GSM, or Momme for silk) are generally more opaque and can handle intricate designs with less show-through. Lighter silks offer a delicate, ethereal quality.

11. The Evolution of Technology: The rise of digital textile printing has made printable silk fabric more accessible than ever, allowing for short runs, intricate details, and rapid prototyping that were once impossible.

12. My First Encounter: I remember ordering a small swatch of pre-treated silk habotai. The difference in how the ink absorbed compared to an untreated piece I had was night and day. The colors were crisp, defined, and vibrant – a true testament to the power of proper preparation.

The Art of Impression: A Deep Dive into Silk Printing Methods

Once you have your beautiful printable silk fabric, how do you actually get your design onto it? There are several methods, each with its own advantages, best suited for different scales, budgets, and desired outcomes. Understanding these will help you choose the right path for your creative vision.

1. Digital Textile Printing (Inkjet Printing):

- How it Works: This is the most popular method for printable silk fabric today. Industrial inkjet printers spray tiny droplets of ink directly onto the pre-treated fabric, much like a paper printer.

- Advantages: Incredible detail, unlimited color palettes, no screen setup costs, ideal for short runs and customization, quick turnaround.

- Disadvantages: Initial machine cost can be high for personal use, requires specialized inks (reactive or acid dyes for silk), fabric needs pre-treatment and post-processing (steaming/washing).

- Personal Scenario: This is my go-to for creating small batches of custom scarves. I can upload a design, print a few, and iterate quickly without significant setup costs. It's a game-changer for indie designers.

2. Screen Printing:

- How it Works: A stencil (screen) is created for each color in the design. Ink is forced through the mesh of the screen onto the fabric, with non-image areas blocked off.

- Advantages: Excellent color opacity, durable prints, cost-effective for large production runs once screens are made.

- Disadvantages: High setup costs for multiple colors, less detail than digital, color limitations (one screen per color), less flexible for design changes.

- Use Case: If you're planning to print thousands of the exact same design on printable silk fabric for a uniform product line, screen printing becomes very economical.

3. Sublimation Printing (Indirect Digital Printing):

- How it Works: The design is first printed onto special transfer paper using sublimation inks. This paper is then placed on the silk fabric and heated under high pressure. The heat turns the ink into a gas, which then permeates and dyes the fabric fibers.

- Advantages: Extremely vibrant, durable, and soft prints (no hand feel), excellent detail.

- Disadvantages: Traditionally works best on synthetic fibers, but specialized coatings or blends can make certain silk fabrics receptive. Requires a heat press.

- Consideration: While not as common for pure silk as reactive digital printing, some pre-treated silk blends can offer good results, but always test first!

4. Hand Painting/Dyeing:

- How it Works: Dyes or paints are applied directly to the silk by hand using brushes, resist techniques (like batik or gutta), or tie-dyeing.

- Advantages: Unique, artisanal, full control over artistic expression, no need for specialized machinery.

- Disadvantages: Time-consuming, inconsistent results (part of its charm!), requires artistic skill, often limited to smaller scale production.

- My Experience: I spent a weekend trying a silk painting workshop, using a resist technique. The results were beautifully organic and unique, though definitely not something I could mass-produce. It’s a wonderful way to connect with the fabric.

5. Block Printing:

- How it Works: A design is carved into a block (wood, linoleum). Ink is applied to the block, which is then pressed onto the fabric.

- Advantages: Rustic, tactile aesthetic, traditional craft, relatively low-tech entry point.

- Disadvantages: Limited detail, repetitive patterns, can be labor-intensive, less suitable for intricate, multi-color designs.

6. Pigment Printing (Digital):

- How it Works: Similar to digital inkjet, but uses pigment inks that sit on the surface of the fabric and are fixed with heat.

- Advantages: No need for extensive post-treatment (steaming/washing), lower water usage, works on a wider range of fibers.

- Disadvantages: Colors can be slightly less vibrant than reactive dyes, prints can have a slightly stiffer hand feel on some fabrics, though advances are making this less noticeable.

7. Reactive Dye Printing (Digital):

- How it Works: Uses reactive dyes that chemically bond with natural fibers like silk. Requires thorough pre-treatment and post-treatment (steaming to fix dyes, washing to remove excess).

- Advantages: Exceptionally vibrant colors, excellent wash fastness, soft hand feel (dyes become part of the fiber).

- Disadvantages: More complex process, higher water and energy consumption for post-treatment.

- My Opinion: For the ultimate color vibrancy and softest hand feel on printable silk fabric, reactive dye digital printing is my absolute favorite. The colors truly sing!

8. Acid Dye Printing (Digital):

- How it Works: Uses acid dyes that bond with protein fibers like silk. Similar pre- and post-treatment requirements to reactive dyes.

- Advantages: Excellent color range and vibrancy, good wash fastness.

- Disadvantages: Requires precise pH control throughout the process.

9. Choosing the Right Ink: The type of ink (reactive, acid, pigment) is paramount. Reactive and acid dyes are generally preferred for silk due to their chemical bonding, resulting in superior color vibrancy and hand feel. Pigments are an option but might slightly alter the silk's luxurious touch.

10. Post-Processing is Key: Regardless of the printing method (especially digital with reactive/acid dyes), proper post-processing (steaming to set the dyes, washing to remove excess ink and pre-treatment chemicals) is absolutely crucial for color fastness and fabric feel.

11. Home vs. Professional: While some desktop inkjet printers can be modified for fabric (often using pigment inks on specially coated fabric sheets), for high-quality, continuous yardage of printable silk fabric, professional printing services are usually the way to go.

12. Consider the Environmental Impact: When choosing a method, consider the water and energy consumption, and the chemicals involved. Some services prioritize eco-friendly dyes and processes.

From Concept to Creation: Designing for Your Printable Silk Project

The beauty of printable silk fabric lies in its ability to bring your most intricate designs to life. But translating a digital concept to a physical textile requires a thoughtful approach to design, ensuring your vision is perfectly rendered on this luxurious canvas.

1. High-Resolution Matters: Always start with high-resolution artwork. For textile printing, 150-300 DPI (dots per inch) at the final print size is generally recommended. Low-resolution images will appear pixelated and blurry on fabric.

2. Color Mode: RGB vs. CMYK: Most digital textile printers work in RGB (Red, Green, Blue) color space, as do monitors and cameras. However, some professional print bureaus might ask for CMYK (Cyan, Magenta, Yellow, Black). Clarify this with your printer. Working in RGB generally allows for a wider gamut of vibrant colors, which silk handles beautifully.

3. Seamless Repeats for Yardage: If you're designing fabric by the yard for apparel or home décor, mastering seamless pattern repeats is crucial. Software like Adobe Photoshop or Illustrator can help create tileable patterns that flow continuously.

4. Consider Scale and Proportion: How will your design look when printed large on a dress versus small on a pocket square? Print a small swatch or mockup to check the scale before committing to a large run.

5. Understanding Color Management Profiles: Professional printers use ICC (International Color Consortium) profiles to ensure color accuracy from screen to fabric. Discuss their preferred profiles and calibration methods to minimize color shifts.

6. The Impact of Fabric Base Color: While silk is typically white or off-white, remember that your design will be printed *on* this base. Very sheer silks might allow some of the background to show through, affecting color perception.

7. Vector vs. Raster Graphics:

- Vector (e.g., AI, SVG): Ideal for sharp lines, logos, and scalable designs without loss of quality. Great for clean, graphic patterns.

- Raster (e.g., JPG, PNG, TIFF): Best for photographs, intricate illustrations, and designs with gradients or textures. Ensure high DPI.

8. Test Swatches are Your Best Friend: I cannot stress this enough! Always, always order a test swatch of your design on your chosen printable silk fabric before a full production run. This allows you to check colors, scale, and overall effect. I once skipped this, confident in my screen calibration, only to find the "ocean blue" was more "pond green" on the actual fabric. Lesson learned!

9. Design for the Drape: Consider how the silk will flow and drape. A linear, rigid design might look fantastic flat, but could become distorted or less appealing on a flowing garment. Organic, fluid designs often work wonderfully with silk's natural movement.

10. Embrace the Sheen: Silk's natural luster can enhance your design. Think about how colors will interact with the fabric's reflective qualities. Bold colors can appear even more vibrant, while delicate pastels can take on an ethereal glow.

11. Software Choices:

- Adobe Photoshop: Excellent for raster graphics, photographic prints, and complex textures.

- Adobe Illustrator: Perfect for vector patterns, sharp lines, and scalable designs.

- Procreate (iPad): Great for hand-drawn digital art that translates beautifully onto fabric.

- Affinity Designer/Photo: More budget-friendly alternatives with powerful features.

12. Beyond the Print: Embellishments: Consider how your printed silk design might be enhanced with subsequent embellishments like embroidery, beading, or even laser cutting, opening up another layer of creative possibilities.

Unleashing Creativity: Inspiring Projects & Applications for Printable Silk

One of the most exciting aspects of printable silk fabric is the sheer breadth of creative possibilities it unlocks. From haute couture to heartfelt gifts, your custom designs can find a home on this exquisite material. Here are some inspiring project ideas and applications that showcase the versatility of printed silk.

1. Fashion Apparel:

- Custom Blouses & Dresses: Imagine wearing a unique pattern you designed, perfectly tailored.

- Luxury Linings: Elevate a jacket or coat with a hidden, custom-printed silk lining.

- Statement Skirts: A flowing silk maxi skirt with an original artistic print.

- Evening Wear: Adding bespoke printed silk panels to a gown for a truly unique touch.

- My Dream Project: I once designed a series of celestial patterns for a silk slip dress collection. The way the stars shimmered on the charmeuse was absolutely magical, proving that printable silk fabric is indeed a canvas for dreams.

2. Accessories:

- Art Scarves: The most popular application! Turn your paintings, photographs, or graphic designs into wearable art. I’ve made several as gifts, and they are always cherished.

- Ties & Pocket Squares: Personalized and sophisticated, perfect for special occasions or corporate branding.

- Headbands & Hair Wraps: Add a touch of elegance to any hairstyle.

- Handbag Linings/Exteriors: Create bespoke handbags with unique printed elements.

- Eyemasks: Luxurious and comfortable, especially with a calming or artistic print.

3. Home Décor:

- Cushion Covers: Transform your living space with custom-designed silk throw pillows.

- Wall Hangings & Tapestries: Large-scale art prints on silk can become stunning focal points.

- Luxury Drapes/Curtains: While silk can be delicate in direct sunlight, it adds unparalleled elegance and flow to interior spaces.

- Table Runners: Elevate dinner parties with a custom silk table runner featuring a seasonal or themed design.

- Bedding Accents: Silk pillowcases with subtle, elegant prints for a touch of luxury.

4. Art & Craft Projects:

- Quilting & Patchwork: Incorporate unique silk blocks into fiber art quilts for texture and sheen.

- Doll/Figurine Clothing: For collectors or artisans, create miniature haute couture.

- Embroidered Bases: Print a subtle pattern or guide on silk, then enhance with hand embroidery.

- Mixed Media Art: Silk fabric can be incorporated into mixed media pieces, adding dimension and textile elements.

5. Unique Gifts & Branding:

- Personalized Wedding Favors: Small printed silk pouches or hankies.

- Corporate Gifts: High-end, branded silk scarves or ties for valued clients.

- Artist Merchandise: Sell limited edition prints of your artwork on silk scarves.

- Team/Club Accessories: Custom printed silk sashes or banners.

- Imagine This: A friend of mine, a photographer, started printing her stunning landscape photos onto silk scarves. They became instant bestsellers at local markets, demonstrating the power of printable silk fabric to elevate a product.

6. Children's Items (with care):

- Baby Blankets (lining): A soft, printed silk lining for a special occasion blanket.

- Nursery Decor: Wall art or small banners with whimsical prints.

7. Jewelry Making:

- Fabric Beads: Custom printed silk can be rolled into unique fabric beads.

- Earrings: Lightweight silk can be cut and shaped into unique earring designs.

8. Bookbinding & Journal Covers:

- Use printed silk to create unique, luxurious covers for bespoke books or journals.

9. Fashion Illustration Backdrops:

- Design and print a custom silk backdrop for showcasing fashion illustrations or products.

10. Pet Accessories (Luxurious):

- Custom printed silk bandanas or bow ties for special furry friends.

11. Costume Design:

- For theater or cosplay, printable silk fabric allows for incredibly detailed and authentic-looking historical or fantasy garments.

12. Event Decor:

- Custom silk banners, table drapes, or even printed silk flowers for high-end events.

Navigating the Nuances: Choosing & Sourcing Your Printable Silk Fabric

Choosing the right printable silk fabric is as crucial as the design itself. The type of silk, its weight, and how it’s pre-treated will significantly impact the final look, feel, and durability of your project. Sourcing it correctly ensures quality and reliability.

1. Identify Your Project Needs First: Are you making a flowing scarf, a structured blouse, or a delicate lining? This will guide your choice of silk weave. For example, a crisp silk twill is great for scarves, while a soft charmeuse is better for lingerie.

2. Understand Momme Weight (mm): Silk weight is measured in Momme (pronounced "mom-ee"). Higher Momme means denser, more durable, and often more opaque silk.

- Lightweight (8-12mm): Sheer, delicate, good for scarves, linings, delicate apparel. (e.g., Habotai, Chiffon)

- Medium Weight (14-20mm): Versatile, good drape, suitable for blouses, dresses, scarves, pajamas. (e.g., Charmeuse, Crepe de Chine, Twill)

- Heavy Weight (22mm+): Opaque, durable, luxurious, for structured garments, upholstery (though less common for printing).

3. Pre-treated for Your Printing Method: Ensure the fabric is specifically pre-treated for the printing method you intend to use (e.g., digital reactive dyes, pigment inks). If you’re using a printing service, they will often specify the types of pre-treated silks they offer.

4. Consider the Weave and Texture:

- Charmeuse: Smooth, glossy, luxurious hand. Prints pop with vibrant color. My personal favorite for high-impact designs.

- Crepe de Chine: Matte, slightly textured, excellent drape. Great for more subtle, elegant prints.

- Habotai: Soft, lightweight, slight sheen. Classic scarf silk.

- Twill: Diagonal weave, durable, good for structured items or scarves that need body.

- Chiffon/Georgette: Sheer, ethereal. Designs will be more translucent.

- Raw Silk (Dupioni/Shantung): More textured, slubby. While unique, the texture can interfere with very fine print details.

5. Sampling is Non-Negotiable: Just like with design, always order samples of different printable silk fabric types you're considering. Feel them, drape them, and if possible, print a small test pattern on each to compare color vibrancy and hand-feel.

6. Reputable Suppliers for Print-Ready Silk:

- Online Fabric Stores (Specialized): Many online retailers now offer "print-ready" or "PFP (Prepared For Printing)" silk fabrics. Look for those specifically catering to digital textile printing.

- Textile Printing Bureaus: If you're using a professional printing service, they often have their own curated selection of pre-treated silks and can advise you on the best choice for your design and project.

- Wholesale Fabric Distributors: For larger quantities, wholesale suppliers can offer better pricing.

- Specialty Craft Stores (Limited): Some higher-end craft stores might carry small quantities, but often at a premium.

7. Check for Certifications: For eco-conscious creators, look for suppliers who offer Oeko-Tex Standard 100 certified silks, ensuring they are free from harmful substances. Some might even offer GOTS (Global Organic Textile Standard) certified organic silks.

8. Minimum Order Quantities (MOQs): Be aware that some suppliers or printing services may have MOQs, especially for custom printing. This is where researching "no minimum custom fabric printing" services can be helpful for small batches.

9. Lead Times: Factor in lead times for ordering fabric and for the printing process, especially if you have a deadline. Custom printing takes time!

10. The Cost Factor: Printable silk fabric is an investment. Prices vary widely based on Momme weight, silk type, supplier, and whether it’s pre-treated. Balance your budget with your quality expectations.

11. Storage of Unprinted Fabric: Store your unprinted printable silk fabric in a cool, dry place, away from direct sunlight, preferably rolled rather than folded, to avoid creases that could affect printing.

12. My Sourcing Tip: I've found success by starting with smaller, specialized online textile printing companies. They often have excellent customer service and are happy to guide you through their fabric options, even sending out small sample packs, which is incredibly helpful when you're just starting out.

The Care & Keeping of Your Printed Silk Treasures

You’ve invested time, creativity, and resources into your beautiful custom printable silk fabric creations. Now, how do you ensure they remain vibrant, luxurious, and last for years to come? Proper care is paramount. Silk is delicate, but with the right approach, it’s surprisingly durable.

1. Always Check the Printer's Instructions: The first and most important rule: defer to the care instructions provided by your fabric printer or the dye manufacturer