Have you ever needed a professional-looking ID card, a custom loyalty card for your small business, or even just a durable, personalized tag for your luggage, and found yourself staring blankly at online options, wondering how on earth people make them? Trust me, I’ve been there. My first attempt at a "professional" ID for a local community event ended up being a flimsy paper printout laminated badly, curling at the edges within an hour. That cringe-worthy experience set me on a mission to master the art of printable PVC cards, and what I discovered revolutionized how I approach small-batch, high-quality printing.

This isn't just about printing; it's about empowerment. The ability to produce sleek, durable, and highly customizable cards right from your home or office is a game-changer for entrepreneurs, event organizers, hobbyists, and anyone looking for a touch of professional polish. In this guide, we'll demystify the process, from understanding the different types of cards to nailing that perfect print, ensuring you avoid the rookie mistakes I certainly made.

Unlocking the Power of Printable PVC Cards: What Are They Anyway?

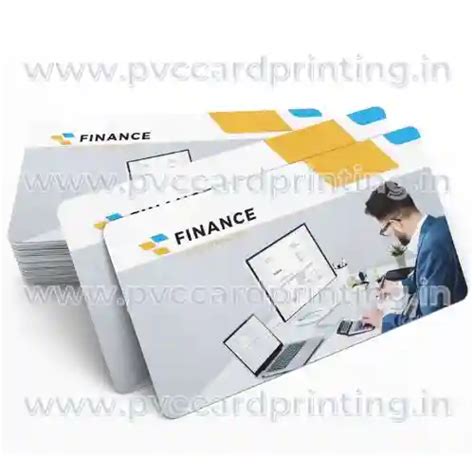

Before we dive into the how-to, let's talk about the "what." Printable PVC cards are essentially blank plastic cards, similar to credit cards, designed to be printed on using specialized printers. Unlike paper, they offer unparalleled durability, water resistance, and a professional feel. They're not just for identification; their versatility is truly astounding!

Here's why they're a game-changer and what you need to know about them:

- Built to Last: Say goodbye to frayed edges and coffee stains. PVC cards are incredibly robust, standing up to daily wear and tear far better than laminated paper. I've had some custom membership cards I printed years ago that still look brand new.

- The Look and Feel of Professionalism: There’s an undeniable tactile difference with plastic cards. They immediately elevate the perceived value of whatever they represent, whether it's a VIP pass or a business card.

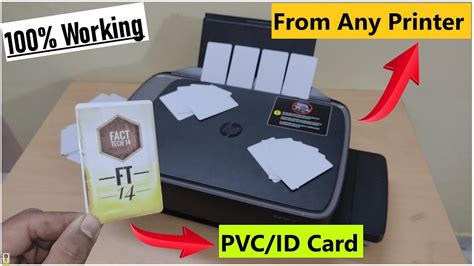

- Inkjet vs. Thermal: Know Your Tech: This is crucial. Most consumer-grade printable PVC cards are designed for inkjet printers (yes, your regular desktop printer, with an adapter tray!). Professional setups often use thermal dye-sublimation printers, which offer superior image quality and speed but come with a heftier price tag. For most DIY projects, inkjet is your friend.

- Standard Sizes Reign Supreme: Just like credit cards, most printable PVC cards come in the CR80 standard size (3.375 x 2.125 inches), making them compatible with most cardholders and wallets.

- Specialty Options Galore: Beyond basic white, you can find magnetic stripe cards, RFID/NFC-enabled cards for access control, and even frosted or metallic finishes. The possibilities for customizable PVC cards are endless.

- Cost-Effective for Small Runs: For businesses that don't need thousands of cards, printing your own is significantly more affordable than outsourcing, especially when considering reprints or minor design changes.

- Surface Matters: Look for cards specifically labeled "inkjet printable PVC" or "thermal printable." The coating on these cards is designed to absorb ink or bond with thermal dyes for crisp, smudge-free results.

- Understanding "Composite PVC": Some cards are a blend of PVC and other plastics. While still durable, pure PVC cards are often preferred for thermal printing due to their consistent heat properties.

- Environmental Considerations: While plastic, many manufacturers are now offering recycled PVC or even bio-PVC options, addressing some environmental concerns.

Gearing Up: Choosing the Right Printer & Cards for Your Project

So, you're ready to dive in. But what do you need? This isn't like printing a document; there are specific tools that make the process smooth and successful. This is where I learned the hard way that not all printers are created equal for this task!

- Inkjet Printer with a PVC Tray: Your Best Friend: For home users and small businesses, an inkjet printer is typically the most accessible option. Crucially, you'll need one that supports a PVC card tray. Epson and Canon models are often cited as compatible, but *always* double-check your printer model's specifications or look for third-party tray attachments. This tray is what holds the card perfectly in place as it feeds through the printer.

- Thermal Printers: The Professional's Choice: If you're printing hundreds or thousands of cards, or require ultra-high security features like holograms, a dedicated thermal PVC card printer (like those from Fargo, Zebra, or Datacard) is the way to go. They use heat to transfer dye onto the card, creating incredibly durable and vibrant prints.

- Quality Inkjet PVC Cards: Don't skimp here! Cheap cards can lead to streaking, poor ink absorption, and frustrating reprints. Look for cards with a specialized coating designed for inkjet printing, often labeled "inkjet printable PVC" or "inkjet PVC ID cards." I once bought a batch of generic cards, and the ink just beaded up – a total waste of time and money.

- Ink Compatibility: While standard dye-based inks often work, some users report better results with pigment-based inks for greater water resistance on PVC. Consult your printer's manual or online forums for specific recommendations for printing on PVC cards at home.

- Cleaning Kits are Non-Negotiable: Both inkjet and thermal printers benefit from regular cleaning. Dust and debris are the enemy of crisp prints. A simple cleaning kit for your printer can extend its life and improve print quality significantly.

- Card Thickness Matters: Most PVC cards are 30 mil thick (standard credit card thickness). Ensure your printer and tray can accommodate this. Thinner or thicker cards might cause feeding issues.

- Consider a Laminator (Optional but Recommended): For maximum durability, especially for cards that will see heavy use (like membership cards), a simple card laminator can add an extra layer of protection, sealing in the ink and preventing scratches.

Design Like a Pro: Software & Tips for Stunning Visuals

Having the right hardware is only half the battle. What goes *on* the card is just as important! This is where your creativity truly shines, transforming a blank plastic canvas into something impactful.

- Graphic Design Software is Key: You'll need design software that allows for precise measurements and high-resolution output. Adobe Photoshop, Illustrator, GIMP, or even Canva (with custom dimensions) are popular choices. Ensure your canvas size matches the CR80 card dimensions exactly.

- High-Resolution Images Only: Pixelated logos or blurry photos will ruin the professional look. Aim for 300 DPI (dots per inch) for all images and graphics used on your card designs.

- CMYK vs. RGB: While most printers use CMYK (Cyan, Magenta, Yellow, Black) for printing, many design programs default to RGB (Red, Green, Blue). Convert your design to CMYK before printing to ensure color accuracy and avoid unexpected shifts. I’ve seen vibrant on-screen designs turn dull on print because I forgot this step.

- Bleed & Safety Margins: Just like professional print jobs, allow for a "bleed" (extend your background design slightly beyond the cut edge) and keep important elements within a "safety margin" (a small buffer from the edge) to prevent them from being cut off.

- Utilize Templates: Many card manufacturers or online resources offer free PVC ID card design software templates. These are fantastic starting points, ensuring correct dimensions and layout.

- Font Choice Matters: Choose legible fonts, especially for small text like contact information or ID numbers. Sans-serif fonts (like Arial, Helvetica, or Open Sans) are generally clearer than elaborate serif fonts for card printing.

- Proofread, Proofread, Proofread: A simple typo on a durable PVC card is a lasting mistake. Get multiple sets of eyes on your design before hitting print. My go-to method is printing a draft on paper first to catch any last-minute errors.

- QR Codes & Barcodes: Easily integrate QR codes for quick website access or barcodes for inventory/membership scanning. Ensure they are generated at high resolution for reliable scanning.

- Layering for Depth: Use layers in your design software to separate elements like backgrounds, text, and photos. This makes editing much easier and gives you more control over the final look.

Beyond IDs: Creative & Practical Uses You Haven't Considered

While ID cards are a primary use, the utility of printable PVC cards stretches far beyond. Let your imagination run wild!

- Loyalty & Membership Cards: Create custom loyalty cards for your cafe, salon, or retail store. Offer punch cards or QR code-based loyalty programs. This is where I truly saw the return on investment for my PVC card setup.

- Business Cards That Stand Out: Tired of flimsy paper business cards? PVC cards offer a premium, memorable alternative that recipients are less likely to discard. Imagine a frosted PVC business card – instantly impressive!

- Gift Cards: Design beautiful, durable gift cards for your products or services. They look professional and can be easily recharged or tracked.

- Access Control & Key Cards: For small offices, gyms, or community centers, PVC cards with magnetic stripes or RFID chips can be programmed for secure access. (Note: this requires specialized cards and a compatible encoder).

- Event Badges & VIP Passes: For concerts, conferences, or festivals, sturdy PVC badges are far more professional and durable than paper alternatives. They also make great souvenirs.

- Luggage Tags: Create personalized, durable luggage tags that won't tear off during transit. A great way to use up extra cards!

- Collectible Cards/Game Pieces: For board game designers or collectors, PVC cards can be used to create custom game cards or collectible art pieces that are robust and can withstand frequent handling.

- Equipment Tags: Label equipment, tools, or even plants in a garden with durable, weather-resistant PVC tags.

- Mini Signage/Display Cards: Use them for price tags in a boutique, mini instructional signs, or product descriptions at craft fairs.

Troubleshooting & TLC: Keeping Your PVC Printing Smooth

Even with the best equipment and design, occasional hiccups happen. Knowing how to troubleshoot common issues and properly maintain your gear will save you a lot of frustration and wasted cards. Don't be like me and ignore a streaky print, only to ruin a whole batch!

- Streaky or Faded Prints:

- Inkjet: Your printer nozzles might be clogged. Run a nozzle check and head cleaning cycle. Your ink cartridges might be low.

- Thermal: The print ribbon might be nearing its end, or the print head might be dirty.

- Cards Not Feeding Properly:

- Inkjet: Ensure the PVC tray is correctly seated and the cards are loaded squarely. Check for dust or debris in the paper path.

- Thermal: The card hopper might be empty, or cards might be stuck. Ensure cards are correctly aligned.

- Smudging:

- Inkjet: The ink might not be drying properly on the card's surface. Ensure you're using inkjet printable PVC cards with the correct coating. Give cards time to dry before handling, especially with high ink coverage.

- Thermal: Less common, but can indicate an issue with the ribbon or print head temperature.

- Dots or Specks on Prints:

- This is often due to dust or lint on the card surface or within the printer. Use a lint-free cloth or a cleaning roller (for thermal printers) to clean cards before printing.

- Color Inaccuracy:

- Ensure your design software is set to CMYK. Calibrate your monitor and printer if precise color matching is critical. Print a test swatch on paper first.

- Printer Maintenance is Crucial:

- Inkjet: Regularly run print head cleaning cycles. Keep your printer dust-free when not in use.

- Thermal: Use manufacturer-recommended cleaning kits, including cleaning cards and swabs for the print head and rollers. This is my favorite strategy because it saved me countless times from expensive print head replacements!

- Store Cards Properly: Keep blank PVC cards in their original packaging, away from direct sunlight, extreme temperatures, and dust to prevent warping or contamination.

The Cost Factor: Budgeting for Your PVC Card Printing Journey

Understanding the investment involved helps set realistic expectations and ensures you get the most bang for your buck. This isn't just a one-time purchase; it's an ongoing process.

- Initial Printer Investment:

- Inkjet with Tray: If you already own a compatible inkjet printer, the tray itself is relatively inexpensive (typically $10-$30 USD). If you need a new printer, factor in its cost ($100-$300+).

- Dedicated Thermal Printer: This is the largest upfront cost, ranging from a few hundred dollars for basic models to several thousands for high-volume, feature-rich machines.

- Cost Per Card:

- Blank PVC Cards: These vary significantly based on type (plain, magnetic, RFID), quantity purchased, and supplier. Bulk purchases always reduce the per-card cost. Expect to pay anywhere from $0.10 to $1.00+ per card.

- Ink/Ribbon: This is an ongoing operational cost. For inkjet, standard ink cartridges. For thermal, specialized ribbons (color YMCKO or monochrome). This cost can add $0.10 to $0.50 per card or more, depending on coverage and ribbon type.

- Software Costs:

- Free options like GIMP or Canva (basic version) are available. Paid professional software like Adobe Creative Suite involves a subscription.

- Accessories:

- Cleaning kits, card cutters (if printing multiple cards on a larger sheet then cutting down), laminators, and card holders all add to the overall investment.

- Time as a Factor: Don't forget to budget your time! Designing, printing, and troubleshooting all take time, especially when you're starting out. Practice makes perfect, and efficiency improves with experience.

- Return on Investment (ROI): For businesses, consider how much you save by printing in-house versus outsourcing, especially for small, frequent runs. The ability to quickly update designs or print on demand can be invaluable. For personal projects, the ROI is in the pride of creation and the unique, professional results.

Tips for Personalizing Your PVC Card Designs

A generic card is just a piece of plastic. A personalized one tells a story, strengthens a brand, or makes someone feel truly valued.

- Incorporate Brand Elements: Use your company logo, specific brand colors, and unique typography. Consistency builds recognition.

- Add Variable Data: For ID cards or membership cards, use software features to pull data (names, photos, ID numbers) from a spreadsheet directly onto individual cards. This saves immense amounts of manual input.

- Think About Texture/Finish: Beyond the standard gloss, consider matte or frosted PVC cards for a unique feel. Some thermal printers can also apply a subtle watermark or security feature.

- Embrace the Backside: Don't let the back of the card go to waste! Use it for terms and conditions, contact information, a map, or a subtle brand message.

- Beyond Flat Print: While this article focuses on basic printing, remember that professional card printers can also emboss, deboss, or hot foil stamp for truly high-end results.

- A Personal Touch: If creating cards for a small group or personal use, adding a personal quote, a shared inside joke, or a custom graphic makes it truly unique. I find this approach works best for small teams or close-knit communities.

- Consider a QR Code for Dynamic Content: Instead of static information, a QR code can link to an online profile, a frequently updated schedule, or special promotions, giving your cards a digital dimension.

Common Pitfalls: What to AVOID When Printing PVC Cards

Learning from mistakes is great, but avoiding them entirely is even better! Here are some common traps I've seen (and sometimes fallen into) when working with printable PVC cards.

- Using the Wrong Type of Card: Trying to print on "laminated" paper cards or generic plastic instead of specifically "inkjet printable PVC" or "thermal PVC" cards is a recipe for disaster. Ink won't dry, or the thermal ribbon won't transfer. Don't be like me and try to cut corners with off-brand cards; the frustration isn't worth it.

- Forgetting to Clean Your Printer: Dust, lint, and dried ink are the enemy. Neglecting regular cleaning leads to streaks, spots, and can even damage your printer's print head.

- Ignoring Color Profiles (CMYK vs. RGB): Printing a vibrant RGB design onto a CMYK-based printer without conversion can lead to dull, inaccurate colors. Always check your color profile settings.

- Underestimating Drying Time (Inkjet): Inkjet PVC cards need time for the ink to fully set. Stacking them or handling them too soon can cause smudging. Be patient!

- Not Setting Up Bleed & Safety Margins: Cutting off crucial text or having a white border around your intended full-bleed design makes the card look unprofessional.

- Overlooking Proofreading: A typo on a hundred durable plastic cards is a much bigger headache than one on a paper flyer. Double-check everything, especially names and numbers.

- Using Low-Resolution Images: Pixelated logos or blurry photos instantly cheapen the look of an otherwise professional PVC card. Always start with high-resolution assets.

- Ignoring Printer Maintenance Alerts: If your printer is telling you it needs cleaning or a new ribbon, it's not crying wolf. Address it promptly to prevent bigger issues.

- Forgetting to Test Print: Always, always, *always* do a test print, preferably on a scrap PVC card if you have one, or at least on paper to check alignment and colors, before running a large batch.

Ready to Print?

There you have it – your comprehensive roadmap to mastering printable PVC cards. From understanding the basics to troubleshooting tricky prints, you now have the knowledge to create professional, durable, and truly custom cards for any purpose. This journey transformed my own projects, giving them a level of polish I thought was only possible with expensive outsourcing. Now go forth, experiment, and create! The world of durable, custom card printing awaits.