Imagine a world where cutting-edge technology isn't just for the privileged few, but a beacon of hope and practical assistance accessible to almost anyone. That's the reality the 3D printable hand is ushering in. More than just a marvel of modern manufacturing, these innovative devices are changing lives, one custom-fitted digit at a time.

For me, the journey into 3D printing started as a hobbyist fascination with creating intricate models. But it was seeing a friend's radiant smile when their child, who was born with a limb difference, effortlessly picked up a toy with a custom-printed assistive device that truly hit home. It wasn't just plastic and gears; it was connection, independence, and pure joy. This isn't just about printing a cool gadget; it’s about unlocking possibilities.

Whether you're a seasoned maker, a caregiver seeking solutions, an educator looking for an impactful STEM project, or simply curious about the future of assistive technology, you've come to the right place. We're going to dive deep into everything you need to know about these amazing creations, from their profound impact to the practical steps of bringing one to life on your own printer.

---

The Heart of the Matter: Why 3D Printed Hands Matter So Much

The true power of a 3D printable hand lies not in its technical specifications, but in its ability to transform daily life. It's about accessibility, affordability, and personal empowerment.

- Breaking Down Barriers: Traditional prosthetics can cost tens of thousands of dollars, making them unattainable for many, especially in developing countries. A 3D printed hand can often be produced for less than $50 in materials.

- Rapid Customization: Children, in particular, outgrow traditional prosthetics quickly. 3D printing allows for rapid, iterative designs that can be resized or modified as a child grows, minimizing replacement costs and discomfort.

- Empowering Independence: For individuals with limb differences, a functional hand, even a simple one, can open up a world of possibilities – from holding a crayon to riding a bike.

- Community-Driven Innovation: Organizations like e-NABLE, a global network of volunteers, are built around sharing open-source designs and connecting those who need hands with those who can print them. It's a testament to human kindness and collaborative problem-solving.

- Beyond Functionality: Personal Expression: Imagine a hand printed in your favorite color, or designed with a superhero theme. 3D printing allows for a level of personalization unimaginable with traditional methods, turning a medical device into a statement of identity. I once saw a child's face light up when they received a Hulk-themed hand; it wasn't just functional, it was *theirs*.

---

Getting Started: Your First 3D Printable Hand Project

Ready to jump into the world of making? Here’s your roadmap to creating your first functional 3D printable hand. Trust me, the learning curve is rewarding!

- Understanding the Basics: Most 3D printable hands are "passive" or "body-powered." This means they use movement of another part of the body (like a wrist or elbow) to open and close the fingers via a simple tension system.

- Finding Reliable Designs:

- e-NABLE: This is your go-to resource. Their website (e-NABLE.org) hosts a repository of vetted, open-source designs, complete with detailed assembly instructions and material recommendations.

- Thingiverse & MyMiniFactory: Search for "prosthetic hand," "assistive device," or "e-NABLE" models. Always check user comments and ratings for reliability.

- Printer Requirements: Most FDM (Fused Deposition Modeling) printers capable of printing PLA or PETG will work. You don't need an industrial-grade machine. A standard desktop printer like an Ender 3 or Prusa Mini can get the job done.

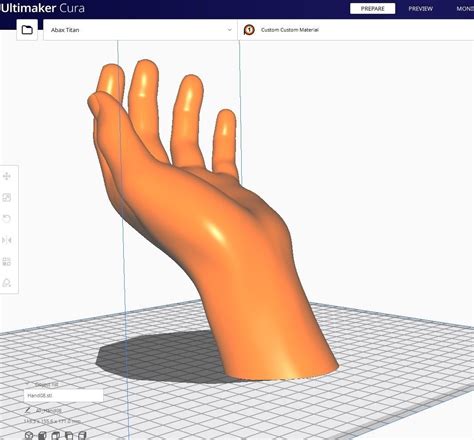

- Essential Software:

- CAD Software (Optional but Recommended): Fusion 360, Tinkercad (beginner-friendly), or SolidWorks for design modifications.

- Slicer Software: Cura, PrusaSlicer, or Simplify3D to prepare your model for printing. This is where you set print quality, supports, and infill.

- Initial Setup & Calibration: If you're new to 3D printing, focus on getting your bed level and your first layer perfect. Many common pitfalls stem from poor initial calibration. Don’t be like me and forget to calibrate your printer before a critical print – you'll regret it later!

---

Beyond the Basics: Advanced Designs & Functionality

Once you've mastered the fundamentals, the world of 3D printed prosthetics expands significantly. This is where the true innovation in biomedical engineering meets accessible fabrication.

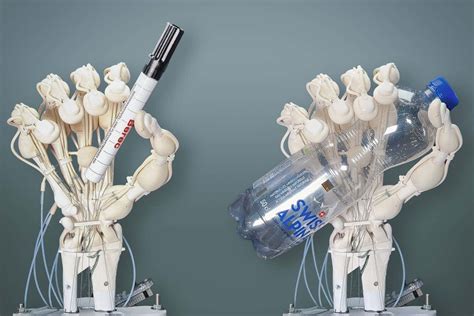

- Myoelectric Hands: These advanced designs incorporate sensors that detect electrical signals from remaining muscles, allowing for more intuitive control of the hand. This is complex and requires specialized electronics and programming.

- Task-Specific Devices: Not all hands are designed for general use. Some are engineered for specific activities, like holding a fishing rod, playing an instrument, or gripping tools. This specialization maximizes functionality for a particular need.

- Modular & Customizable Systems: Some designs allow for interchangeable finger attachments or palm designs, offering greater versatility for the user. Think of it like a toolbox for the hand.

- Integrated Electronics & Feedback: Beyond just motor control, some experimental designs include haptic feedback (touch sensation) or even rudimentary temperature sensing, pushing the boundaries of what a 3D printed assistive device can do.

- Articulated Fingers & Complex Mechanisms: While basic hands use simple tension, more advanced models incorporate intricate gearing or tendon systems for smoother, more lifelike finger movement. This is my favorite strategy for realistic movement, though it adds design complexity.

- Hybrid Solutions: Combining 3D printed components with off-the-shelf parts (like silicone liners or specialized joints) can enhance comfort, durability, and functionality.

---

The Nitty-Gritty: Materials, Printers, & Troubleshooting Your 3D Printable Hand

Successfully printing a functional 3D printable hand requires attention to detail. Here’s what veterans know about the materials and common issues.

- Filament Choices:

- PLA (Polylactic Acid): Common, easy to print, biodegradable. Good for initial prototypes and basic functional hands, but can be brittle.

- PETG (Polyethylene Terephthalate Glycol): More durable, slightly flexible, and less brittle than PLA. Excellent choice for functional parts that need to withstand some stress.

- ABS (Acrylonitrile Butadiene Styrene): Stronger and more heat-resistant than PLA/PETG, but harder to print (requires an enclosure). Less commonly used for hands due to fumes and warping.

- Flexible Filaments (TPU/TPE): Used for specific parts requiring flexibility, like finger joints or liners for comfort.

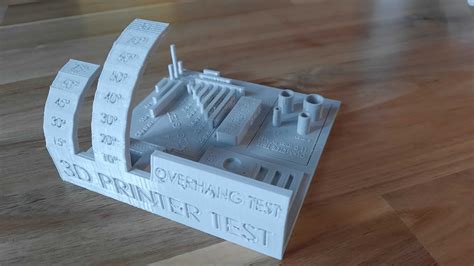

- Printer Settings (Crucial for Reliability):

- Infill: 60-100% infill is often recommended for structural integrity, especially for load-bearing parts.

- Layer Height: 0.15mm-0.2mm is common for a good balance of detail and strength.

- Supports: Often necessary for overhangs and intricate geometries. Learn how to remove them cleanly!

- Print Speed: Slower speeds generally result in stronger, more reliable prints.

- Common Pitfalls & Troubleshooting:

- Warping/Bed Adhesion: Ensure your print bed is clean and properly leveled. Use adhesive aids like glue stick or hairspray.

- Layer Delamination: Can indicate insufficient extrusion temperature or too much cooling.

- Stringing: Often a retraction issue. Adjust retraction distance and speed in your slicer.

- Support Removal Damage: Be gentle! Sometimes, a quick pass with a heat gun can help clean up rough spots.

- Broken Parts: This is where print orientation and material choice really come into play. Orient parts to put stress along layer lines, not perpendicular to them. My first attempt at printing a finger section taught me the hard way about layer strength!

---

Community & Collaboration: Joining the 3D Printed Hand Movement

One of the most inspiring aspects of the 3D printable hand is the incredible global community behind it. This isn't just about technology; it's about people helping people.

- e-NABLE Global Community: As mentioned, e-NABLE is at the forefront. Join their forums, Facebook groups, or local chapters. They provide resources, support, and connect makers with recipients.

- Online Forums & Social Media: Reddit communities (r/3Dprinting, r/prosthetics), dedicated Facebook groups, and Discord servers are excellent places to share your progress, ask questions, and learn from others.

- Maker Faires & Local Meetups: Attending these events can connect you with fellow enthusiasts, share insights, and even find opportunities to collaborate on projects.

- Donating Your Time & Skills: If you have a 3D printer and the willingness to learn, you can contribute directly by printing hands for those in need through organizations or individual requests.

- Sharing Your Own Designs: If you're an experienced CAD user, consider designing your own modifications or entirely new assistive devices and sharing them open-source. This further fuels innovation in the field of open source prosthetic designs.

---

Ethical Considerations & The Future of the 3D Printable Hand

While the possibilities are exciting, it’s important to approach the 3D printable hand with a clear understanding of its implications and future trajectory. This is a rapidly evolving field, blending innovation with profound human impact.

- Safety & Durability: While amazing, 3D printed hands are not always medical-grade devices. It's crucial to understand their limitations and ensure they are used safely and appropriately. They should not replace medically prescribed prosthetics unless guided by a professional.

- Fit & Comfort: A poorly fitted device can cause discomfort or even injury. The importance of proper measurement and customization cannot be overstated.

- Long-Term Impact: We're still learning about the long-term effectiveness and psychological impact of 3D printed assistive devices. Ongoing research and user feedback are vital.

- The Rise of Bio-Integration: While still largely conceptual for affordable 3D prints, the future could see better integration with the human body, potentially leading to more advanced, truly bionic hand solutions accessible to a wider population.

- Education & Awareness: Promoting awareness of 3D printing's potential in assistive technology can inspire the next generation of engineers, designers, and healthcare professionals.

- The Future is Open Source: The continued proliferation of open-source designs and collaborative communities will be key to making these life-changing devices even more accessible and effective worldwide.

---

Tips for Personalizing Your 3D Printed Hand

Creating a 3D printable hand isn't just about functionality; it's about making it uniquely *theirs*. Here are some ways to add a personal touch.

- Color Choices: This is the easiest and most impactful personalization. Let the recipient choose their favorite colors for different parts of the hand. I find this approach works best for young recipients; it immediately makes the device more appealing.

- Themes & Decor: Incorporate elements of their favorite superheroes, animals, or hobbies. You can use multi-color printing, custom decals, or even paint safe for plastics.

- Engraving/Embossing: Add their name, initials, or a small inspirational message directly onto the design (if the CAD model allows for modification).

- Functional Add-ons: Does the recipient have a specific hobby? Perhaps a small clip for a guitar pick, a holder for a pen, or a specialized grip.

- Comfort Liners: While not visually personalized, adding soft, 3D printed flexible liners or foam padding can drastically improve comfort and wearability.

---

Common Pitfalls: What to AVOID When Printing 3D Hands

Even seasoned makers can stumble. Learn from common mistakes to ensure your 3D printable hand project goes smoothly.

- Ignoring Measurement Guides: Do NOT skip accurate measurements! A hand that doesn't fit properly is useless and potentially uncomfortable. Double-check all dimensions.

- Using the Wrong Filament: Don't use brittle or unsuitable materials for structural parts. While a flashy color might be tempting, strength and durability are paramount.

- Neglecting Print Settings: Under-extruding, insufficient infill, or poor support settings can lead to weak parts that break easily under stress. A well-calibrated machine is your best friend.

- Rushing Assembly: Take your time with assembly. Ensure all pins, screws, and tension lines are correctly routed and secured. A small mistake can lead to a non-functional device.

- Overpromising Functionality: While amazing, a 3D printed hand isn't a magical bionic limb (yet!). Be realistic about its capabilities and don't create unrealistic expectations for the recipient.

- Ignoring Post-Processing: Don't be like me and forget to clean up rough edges and sharp spots! Smooth surfaces are crucial for comfort and safety, especially for prolonged wear.

---

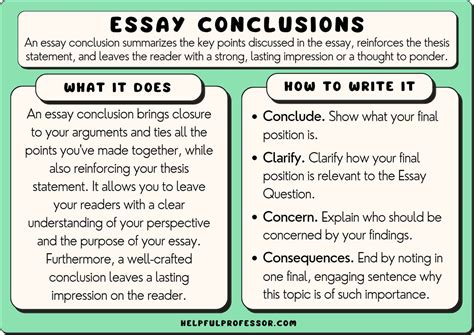

Conclusion

The 3D printable hand represents more than just a technological breakthrough; it's a testament to human ingenuity, empathy, and the power of collaborative communities. From offering affordable solutions to empowering individuals with newfound independence, these devices are a shining example of how future technology can genuinely make a difference.

Whether you're embarking on your first print or delving into advanced designs, remember the profound impact your efforts can have. Now go forth, explore, create, and help spread the magic of the 3D printed hand!