Let’s be honest: there are few things more frustrating in 3D printing than coming back to a tangled spool or a filament snap mid-print. It’s like watching a marathon runner trip at the finish line, but instead of glory, you get a spaghetti monster. Trust me, I’ve been there – spent a whole night trying to salvage a large print only to find the filament had snagged just hours before I woke up. That’s why a reliable 3d printable filament holder isn’t just a nice-to-have; it’s an absolute necessity for smooth, consistent, and stress-free printing.

This isn't just about finding a place for your spools; it's about optimizing your print quality, saving you time, and protecting your precious filament from environmental hazards like dust and moisture. Whether you're a beginner just getting your first printer or a seasoned pro looking to refine your setup, this guide will walk you through the myriad of brilliant, functional, and surprisingly clever 3d printable filament holder designs out there. We’ll explore different types, share hard-won tips, and help you find the perfect solution to keep your filament flowing freely, every single time.

Discover Your Ideal Filament Holder: Categories & Considerations

Finding the right 3d printable filament holder depends heavily on your specific needs, printer setup, and even your printing habits. Here are some categories to help you narrow down the perfect design for your maker space.

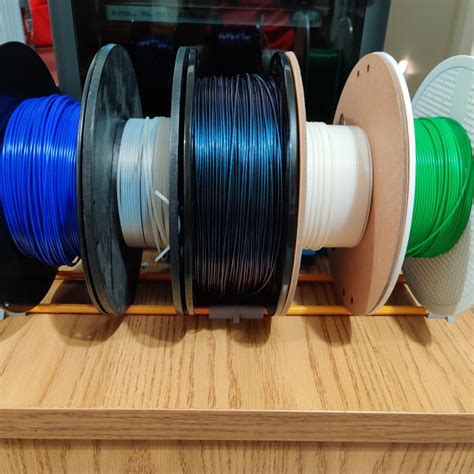

### 1. The Space Savers: Maximizing Your Workbench Real Estate

For many of us, workbench space is prime real estate. These designs focus on keeping your filament neatly organized without overwhelming your workspace.

- Under-Desk Mounts: Perfect for keeping spools out of sight and out of mind, freeing up valuable surface area.

- *Personal scenario:* I used an under-desk mount for my larger spools, which instantly made my small print corner feel much more open and less cluttered.

- Wall-Mounted Solutions: Utilize vertical space, especially great for smaller workshops or garages. Look for designs that allow for quick spool changes.

- Stackable Drawer Systems: Some designs incorporate drawers underneath for desiccant or tools, making them multi-functional.

- Hanging Rack Systems: A simple rod or pipe supported by 3D printed brackets can hold multiple spools vertically or horizontally.

- Fold-Away Designs: Ideal for temporary setups or when you need to clear the area completely.

- Compact Single Spool Holders: When you only need one active spool, these minimal designs are super efficient.

- Corner Units: Designed to fit snugly into corners, utilizing often-wasted space.

### 2. The Enclosure Enthusiasts: Holders for Climate-Controlled Printing

If you're printing with materials like ABS or ASA, an enclosure is a game-changer. These filament holders are designed to live inside or integrate seamlessly with your enclosed setup.

- Internal Enclosure Mounts: Designs that attach directly to the inside walls or frame of your enclosure.

- *Personal scenario:* My enclosed printer desperately needed an internal holder to prevent tangles inside the cramped space, and a simple wall-mounted solution saved countless prints.

- Top-Mounted Spool Holders: If your enclosure is tall enough, a holder mounted to the roof can be very effective.

- Bearing-Assisted Spool Mounts: Essential for smooth feeding, especially important in tight enclosures where friction can be an issue.

- Desiccant Integration: Many designs for enclosed setups incorporate space for desiccant to combat humidity, crucial for consistent ABS prints.

- Pass-Through Systems: For those who prefer to keep their filament outside the enclosure, a well-designed pass-through system is key.

- Heated Filament Dry Boxes: While not strictly "holders," some designs combine holding with active heating to ensure dry filament, perfect for hygroscopic materials.

- Minimalist In-Situ Holders: Designed to take up the least amount of space possible within the confines of an enclosure.

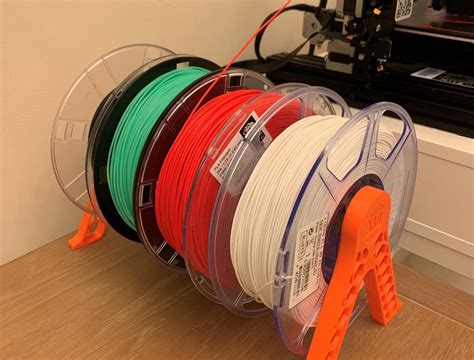

### 3. The On-Printer Organizers: Direct-Mount Solutions

Sometimes, the simplest solution is to keep your filament right where it's needed: on the printer itself. These holders replace or augment your printer's stock spool holder.

- Replacement Spool Holders: Often designed with better bearings or a more stable base than the default, stock solution.

- *Personal scenario:* The stock holder on my Ender 3 was always a bit wobbly, so printing a beefier, bearing-equipped replacement was one of my first upgrades.

- Side-Mounted Add-ons: Attach to the printer's frame, offering an alternative position for the spool.

- Top-Gantry Spool Holders: Mount to the top bar of your printer (common on Cartesian printers), keeping the filament path direct.

- Multi-Spool Attachments: Some clever designs allow you to mount multiple smaller spools directly to the printer for quick color changes or multi-material prints.

- Filament Guide Integration: Many on-printer designs include built-in filament guides to ensure a smooth path to the extruder.

- "Dry Box" Add-ons: Smaller, printable enclosures that sit directly on the printer, keeping a single spool dry.

- Modular Attachments: Designs that allow you to easily add or remove different sizes of spool holders based on your current project.

### 4. The Moisture Warriors: Integrated Drying & Storage

Humidity is the silent killer of filament. These 3d printable filament holder designs are all about keeping your precious spools bone dry.

- Desiccant-Equipped Boxes: The most common form, these are sealed containers with space for desiccant packets, preventing moisture absorption.

- *Personal scenario:* I learned the hard way about wet PETG – the popping sounds were infuriating! Building a few desiccant-packed boxes for my spools was a game-changer for print quality.

- Passive Airflow Designs: Some clever designs allow for minimal, controlled airflow to prevent moisture buildup without active drying.

- Roll-Through Dry Boxes: Filament can be fed directly from the dry box to the printer, ensuring it stays dry during printing.

- Modular Desiccant Inserts: Designs that allow you to easily swap out or replenish desiccant.

- Airtight Seal Designs: Crucial for true moisture protection, look for models that print with channels for rubber gaskets or O-rings.

- Indicator Holders: Some advanced designs include slots for humidity indicator cards so you can easily check moisture levels.

- Integrated Hygrometers: For the truly dedicated, printable boxes that accommodate small digital hygrometers to display precise humidity levels.

### 5. The Printability & Durability Focus: Designs That Work

What’s the point of a 3d printable filament holder if it’s a nightmare to print or breaks easily? These categories focus on designs that are optimized for ease of printing and longevity.

- No Support Needed Designs: Print-in-place or cleverly designed models that require minimal to zero supports.

- *Personal scenario:* My favorite designs are always the ones that print flawlessly the first time without needing a surgical removal of supports. Less hassle, more printing!

- Interlocking Parts: Designs that print in smaller, manageable sections and then snap or screw together, avoiding large single prints.

- Robust & Chunky Builds: Designs that prioritize strength and stability over intricate details, using less material but remaining sturdy.

- Minimal Hardware Required: Look for designs that primarily use printed parts, perhaps only needing a few common screws or bearings.

- Tested & Community-Approved: Designs with many makes and positive reviews on platforms like Printables or Thingiverse are usually a safe bet.

- Open-Source & Customizable: Designs where the CAD files are available, allowing you to tweak and modify them to your exact specifications.

- Material-Optimized Designs: Some designs are specifically tailored for printing in PLA, PETG, or even more durable materials, ensuring optimal performance.

Tips for Personalizing Your 3D Printable Filament Holder

While pre-made designs are fantastic, a 3d printable filament holder offers the unique opportunity to truly make it your own.

1. Consider Your Material: PLA is great for most holders, but for heavier spools or if it’s in a warm enclosure, PETG or even ABS will offer better durability and heat resistance. I find PETG to be the best all-rounder for most structural prints like these.

2. Add a Splash of Color: Don't be afraid to print different parts in contrasting colors. It adds a touch of personality to your print station.

3. Integrate Storage: Think about what else you might need nearby. Can you add slots for cutters, tweezers, or even desiccant packets right into the design?

4. Measure Twice, Print Once: Before committing to a full print, measure your spools, your available space, and your printer's dimensions. Scale models or print small test pieces if you're unsure. This is my favorite strategy because it saved me countless times from wasted filament.

5. Branding/Labeling: Consider adding embossed or debossed text to your design for labeling (e.g., "PLA Holder," "PETG Storage") or even your maker logo!

6. Bearing Integration: For any holder that spins, bearings (like 608zz skateboard bearings) are a *must*. They make filament feeding incredibly smooth. Make sure the design accommodates them.

7. Future-Proofing: If you anticipate getting larger spools or different types of filament, look for designs that are modular or easily adaptable.

Common Pitfalls: What to AVOID When Choosing/Printing a Filament Holder

Even with something as seemingly simple as a 3d printable filament holder, there are traps to avoid. Don't be like me and make these mistakes:

- Ignoring Spool Size: Not all spools are created equal. Some holders are designed for specific spool widths or diameters. Don't assume your new 2kg spool will fit a holder designed for 1kg spools. It usually won't, and you'll end up with a useless print!

- Under-Engineering Bearings: A holder without proper bearings, or with bearings that are too small or cheap, will lead to filament drag, tangles, and potentially failed prints. Invest a few bucks in decent bearings.

- Over-Reliance on Friction: Unless it’s a very specific, lightweight setup, a holder that relies solely on friction to spin the spool will cause unnecessary tension on your extruder and potentially lead to grinding or under-extrusion.

- Poorly Sealed Dry Boxes: If your "dry box" isn't truly airtight, it's just a fancy container. Check for designs that incorporate rubber seals or have very tight tolerances.

- Blocking Printer Movement: For on-printer or enclosed solutions, always double-check that the filament holder won't interfere with the print head's travel, bed movement, or any other moving parts.

- Using the Wrong Material: Printing a holder meant to be inside a warm enclosure with standard PLA can lead to warping or softening over time. Use PETG or ABS for higher heat resistance.

- Complex or Support-Heavy Designs for Simplicity: If you just need a basic holder, don't pick a ridiculously complex multi-part design that takes ages to print and clean up. Keep it simple where possible.

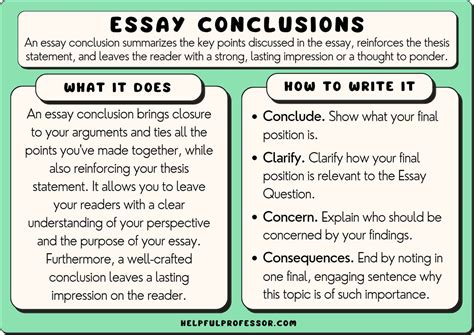

Conclusion

There you have it – a deep dive into the surprisingly vital world of the 3d printable filament holder. From saving precious workbench space to fighting off insidious moisture, the right holder can transform your 3D printing experience from frustrating to fantastic. By leveraging the power of 3D printing, you can create a custom solution that perfectly fits your setup, ensures smooth filament delivery, and ultimately leads to more successful, beautiful prints. So, fire up your printer, pick a design, and go make your printing life a whole lot easier! Your future self (and your printer) will thank you.